Description

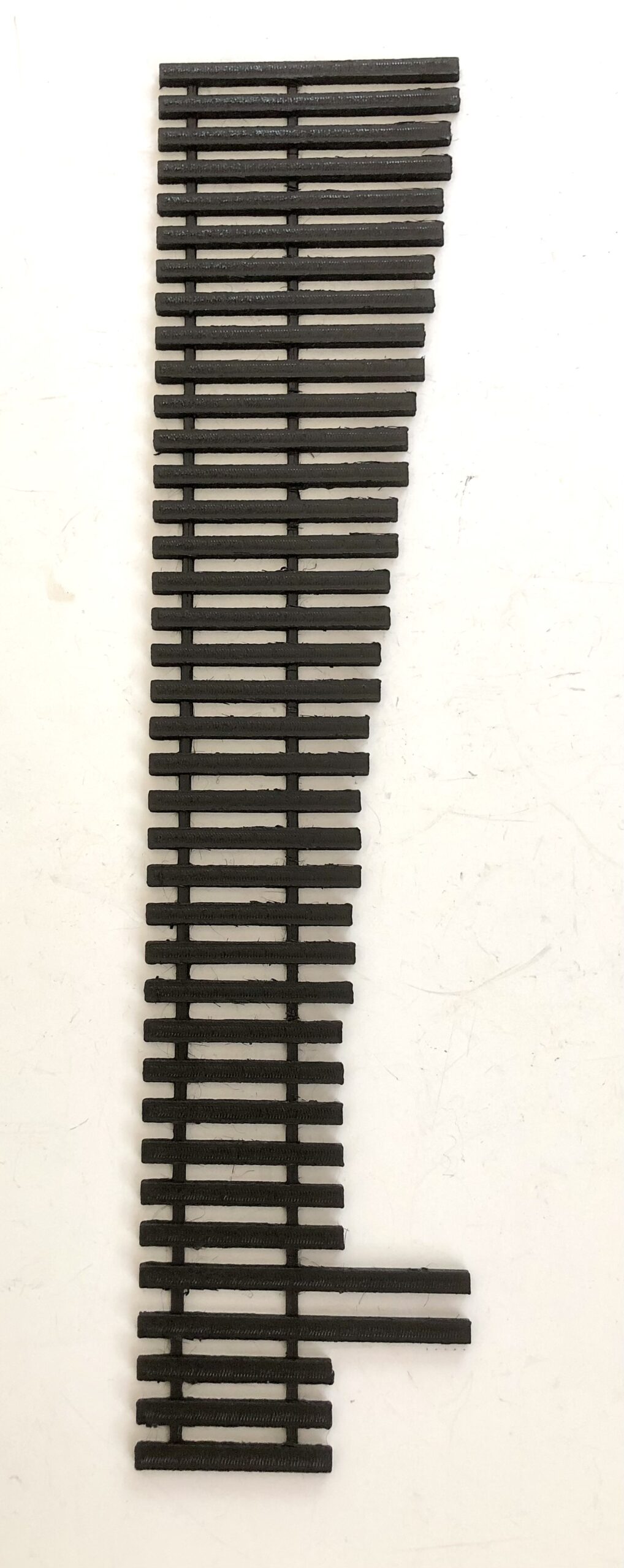

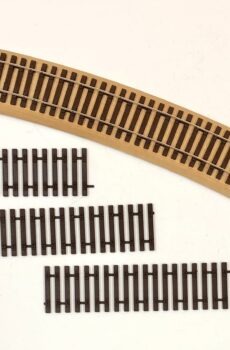

For Sale: All Nation Right Hand #6 Turnout Premium 3D Printed PN#638AN

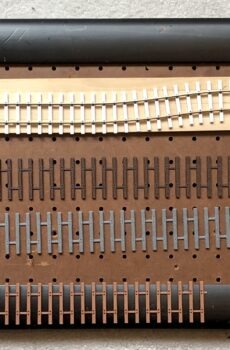

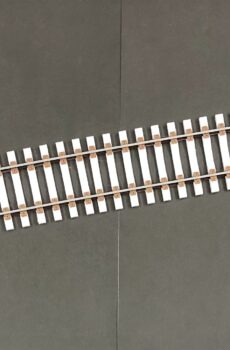

The All Nation Line Premium Grade Railroad Ties in O Scale is especially formulated to out perform the traditional wood tie used by modelers to hand lay track. After much research and thought regarding the physics of spiking into wood ties, our 3D Printed Flex Tie Strips feature the same characteristics as one would witness in the use of a wood tie when spiking down rail.

The following are features that make these premium ties the best on the market.

(1) 95% less likely to bend the spike as opposed to wood if hitting a hard spot.

(2) No pilot holes need to be drilled in order to push the spike into the tie.

(3) Spikes will not tend to release or pop back out over time or with changes in environmental conditions.

(4) And most importantly, the ties do not resonate sound, thus your trains run much more quit around the layout. One exception if the spike is long (i.e. 7/16″) and travels through the tie into hard roadbed beneath the tie, sound may increase.

Take a look at this video describing these premium O Scale Flex Ties.

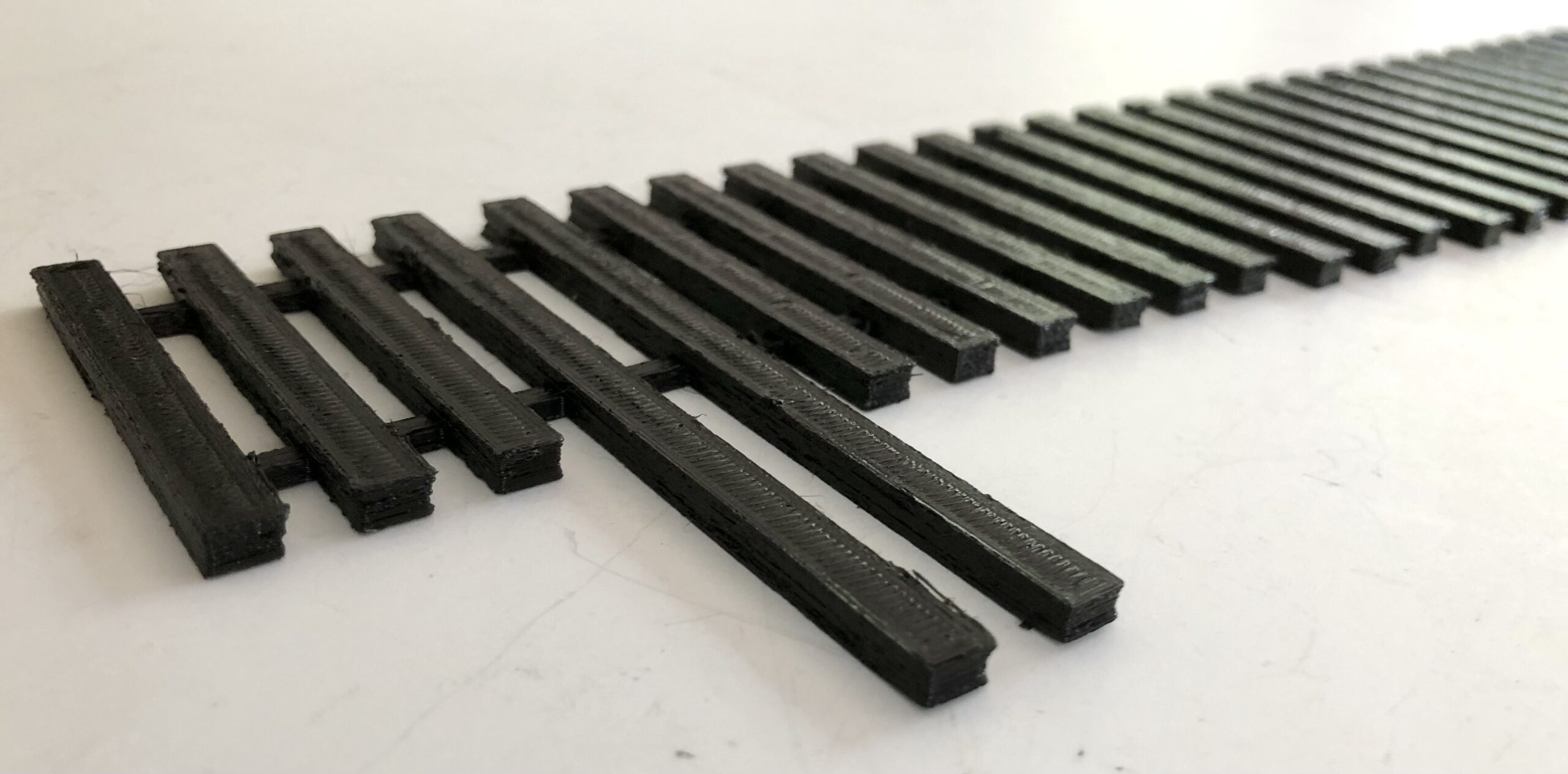

Without taking a deep dive into the science and engineering, some background thoughts as to why this is a better tie. If you think in terms of material science and the relationship of a steel spike or nail that comes into contact with dissimilar material like wood or any other material where it has to hold the rail down and in gauge, there are a number of factors that should be considered. Those factors include such variables as compressive strength, load bearing, and lateral strength. Many variables have no usefulness such as strength in the X & Y plane or high vertical and shear resistance. That means using tricks in the slicr software if a parameter has no optimal usefulness and thus is not preferable.

Really what we are looking for is Isotropic strength in all directions. This gives us uniform strength with the spike interface with the tie. However, this is more complex to print and takes significantly more time to make a set of ties. In addition, we use a premium grade filament such that you will note the ease of which spikes going into the tie and holds very tight. Isotropic strength refers to the mechanical strength of a material that is uniform in all directions. In other words, an isotropic material has the same strength, stiffness, and other mechanical properties regardless of the direction in which force is applied. Consequently, Cystalline plastics and even Amorphous plastics are not ideal for this application.

We will not get into the technology of taking the tie design from the CAD software into the slicr programs and ultimately to the printer. That is a lengthy discussion for a later day or perhaps a video. However, one thing for certain and (5) lasting attribute about the Premium ties is they are extremely durable. Unlike if you slip with your pliers when pushing into a wood tie and deform it, our ties are tough and will not deform in the event you slip with the pliers. We think you will find real value and performance with this product even if it only a short section of mainline on your model railroad layout.

NOTE: Not all types or brands of spikes have been tested such as laser cut of micro sizes. However, the most common spikes used over the years such as All Nation, Walthers, Model Master or Micro-Engineering products work just fine.

Note: Modeler will need to trim away cross hairs between the ties which are a result in the 3D printing. They can be removed with tweezers or small scissors.