Description

For Sale: 3 Rail to 2 Rail Conversion MTH GP40-2 All Nation Single Drive Transmission NO ENGINE BODY O Scale PN#367

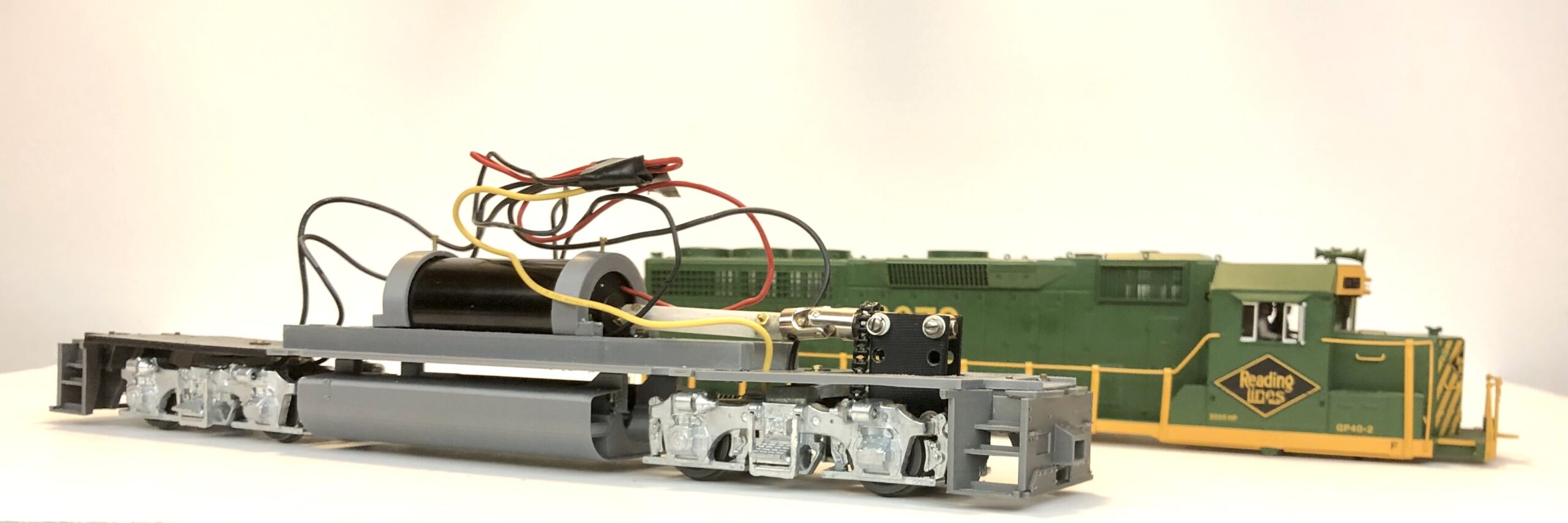

(Note: Photo of engine with shell is for demonstration purposes only. Body engine is NOT included in this sale.)

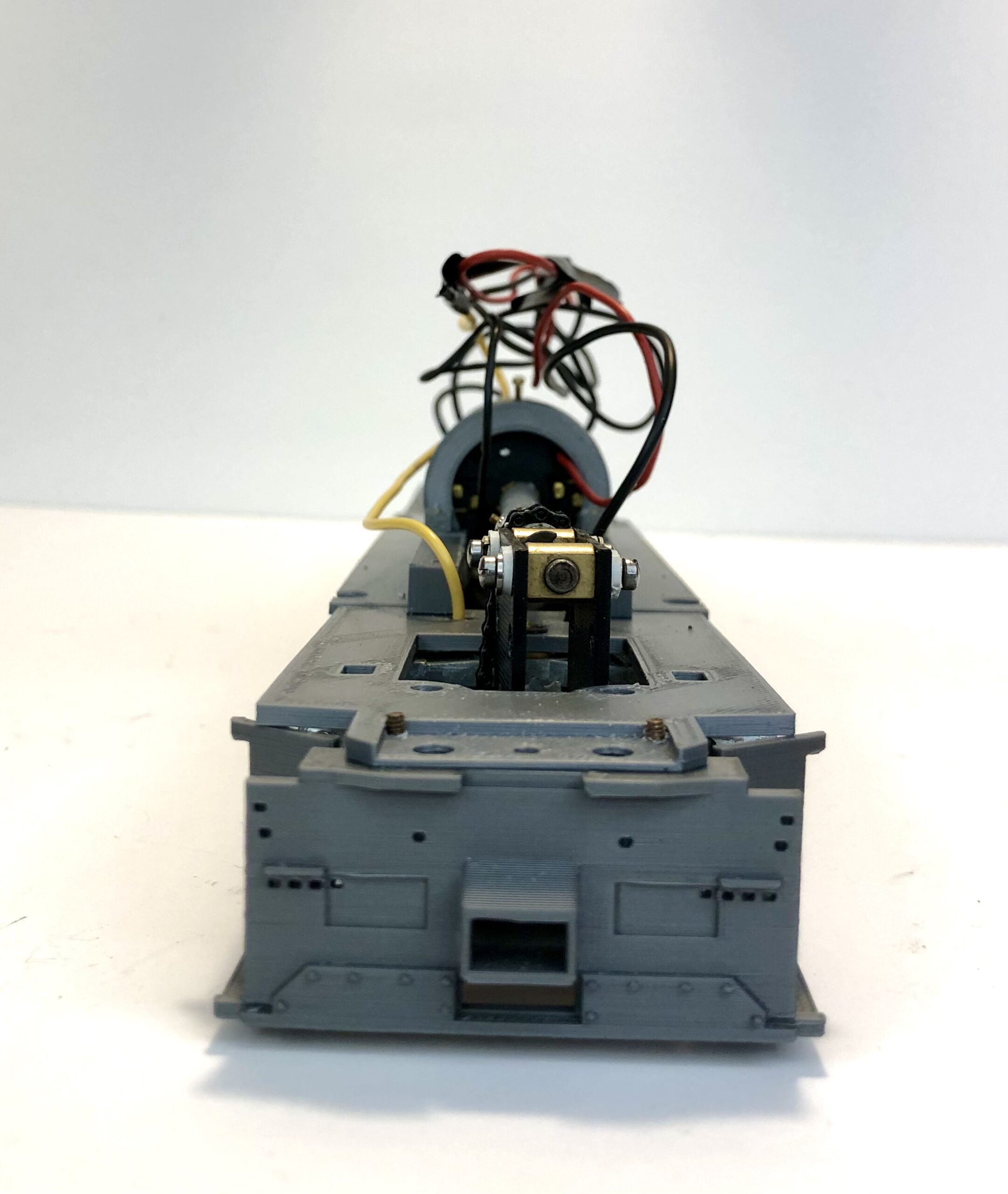

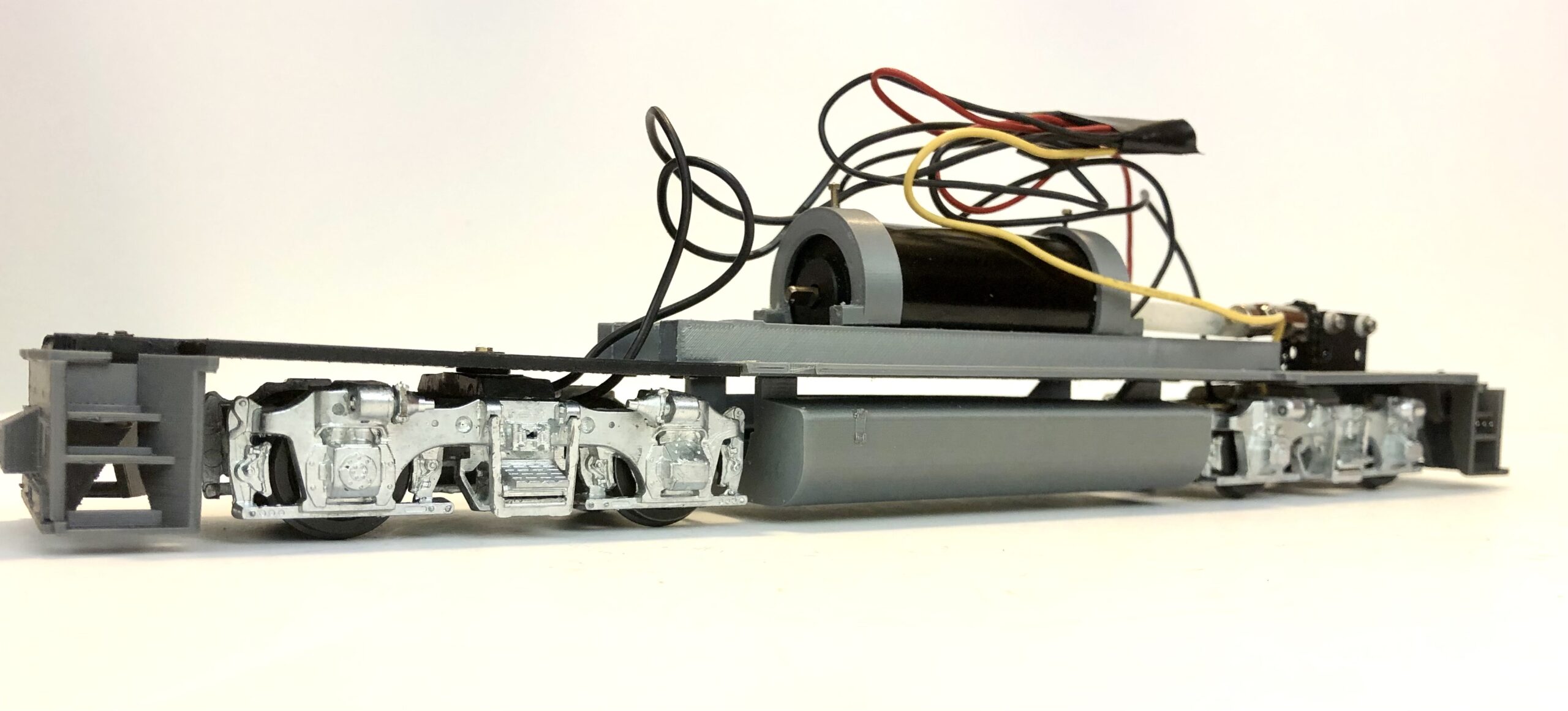

The ever popular GP-40-2 converted from 3 rail is now a single powered locomotive (couplers included) with the world famous All-Nation tower transmission drive power trucks, Custom Hand Crafted to meet your greatest expectations. The engine chassis is formed to fit into the body of a MTH injection molded component with significant scale detail. Temporarily wired for 2 rail DC, the modeler may choose to add Power On Board, or DCC and sound. The new chassis conforms to the MTH engine body, accommodates not only the motor as shown, but also the platforms for the trucks and pilots at both ends. We think you will have generations of fun with this engine on your layout.

As they say in the world of Six Sigma, if you are going to tackle a project, do it right the first time.

For a long time I wanted to convert some of the 3 rail engines to 2 rail operation and over the last several years modelers have contacted me with the same request or desire for assistance with parts and know how. Ready To Run just does not happen over night and I would encourage any modeler to take the initiative to hand craft the necessary work to reach the RTR goal. Engine conversion is not as easy as doing a freight car.

Usually, the engine body is the least of your worries unless it needs some repair or custom paint. The chassis and the mechanism is where the power meets the rails.

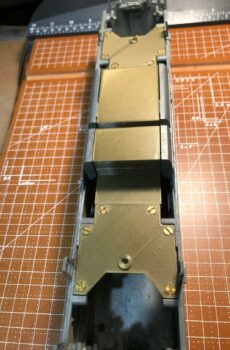

The first thoughts on the pathway toward a conversion such as this is to prioritize what it is you want to achieve. In this case I was looking to have an end result that is a high performance power train. That requires some investment in time to build and keep tolerances close in all aspects of the build. Everything from the zinc die cast trucks to the gearing and shaft connections requires close attention.

The second thought that seems most desirable, based on the long life of All-Nation drives, is to be able to service the mechanism from top to bottom. Thus, every component except the motors can be disassembled and properly maintained over time. Replacement parts can be sources from the All-Nation parts department.

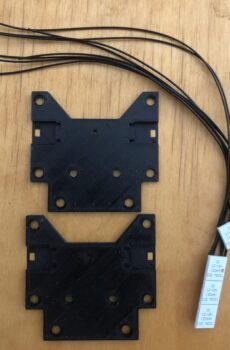

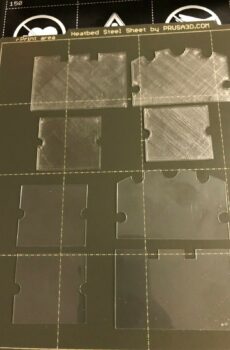

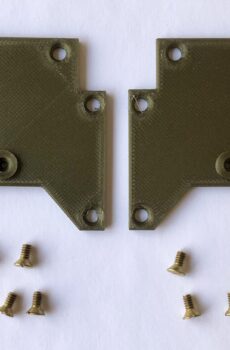

3D Printing has facilitated a much easier pathway to do conversions. One item that complicates the conversion is the many different DC motors available. The brackets most of the time need to be customized to house or mount the motor. However, that is a good thing because now one has the ability to raise or lower the motors in the chassis if so desired. On the other hand, 3D Printing allows us to tweak the sprocket parameters to calibrate it so the tension on the chain drive is optimal.

Like my layout that is a never ending project, I cannot say that my engines are ever finished. I am always going back to work on them even for a minor detail. It is with great pride to see it finally on the rails.

Once completed, the engine obviously needs some breaking in even though the transmission drives were individually bench tested and run with lubrication before installing them into the trucks. Regardless, first time on the tracks after the conversion is complete, the model can creep at very low speed or run full throttle.

The Blomberg Trucks now have ball bearings in the journals and pickup of DC current on all the wheel sets. The drive shaft from the motor to the tower drives are insulated with a soft to the touch plastic tubing to reduce noise vibration.

In order to give you a better perspective on this conversion project, please view this video I put together to document some of the process. Please note my test track bench work amplifies the sound to a huge extent because it acts like a sound board, no homasote or cork has been used to make it quiet and my track work has been deliberately laid down to be rough in order to determine engine and car performance at various speeds.

https://johnwubbel.com/crh/Brass-Investments-Project-Web-Show/GP40-2_Conversion.mp4

These conversions are really hand crafted (vs factory made) it is really a plus I think and adds the extra touch of quality of the product.

Thank you and we hope you enjoy participating in the craftsmanship as we do.