Description

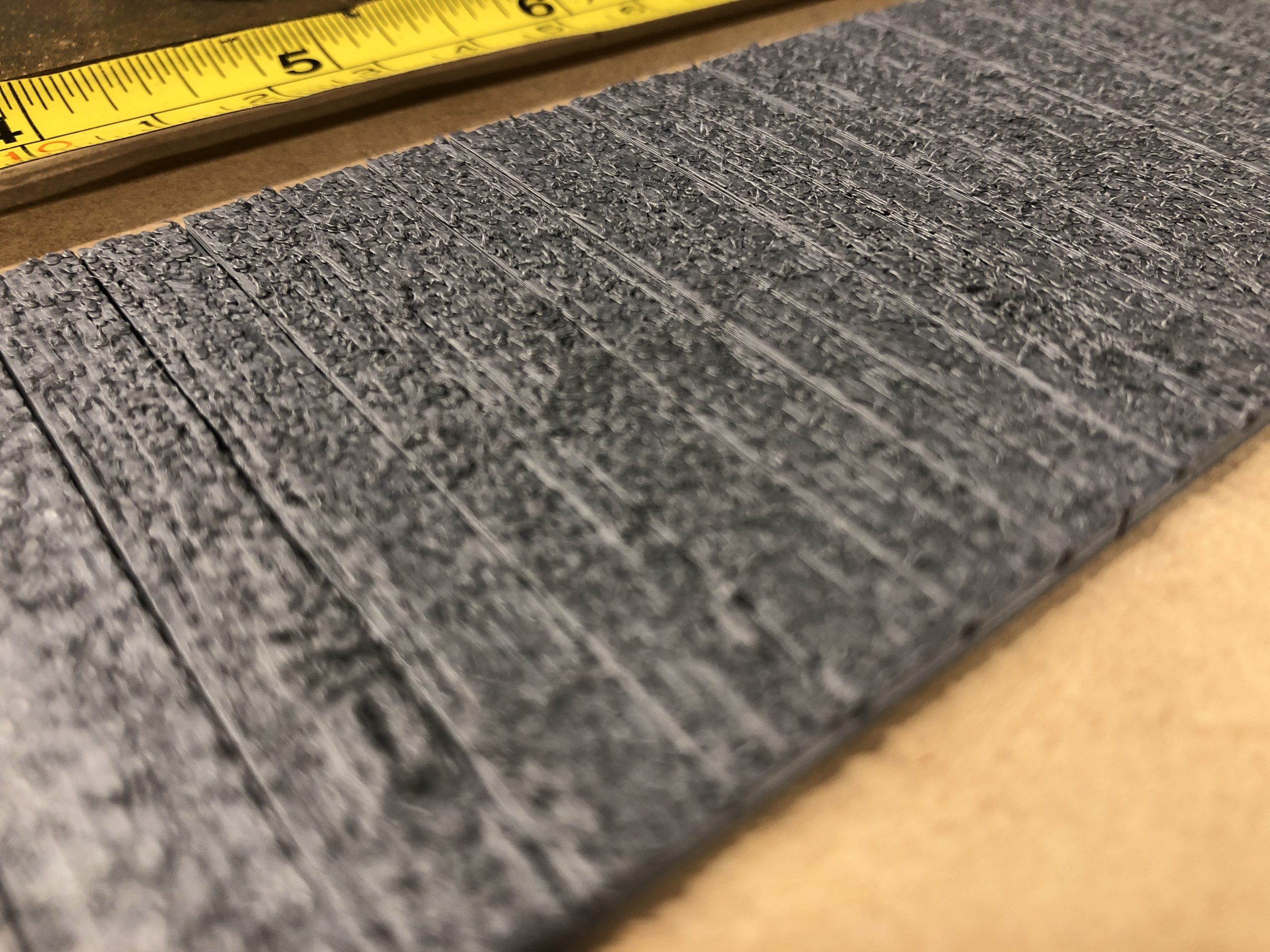

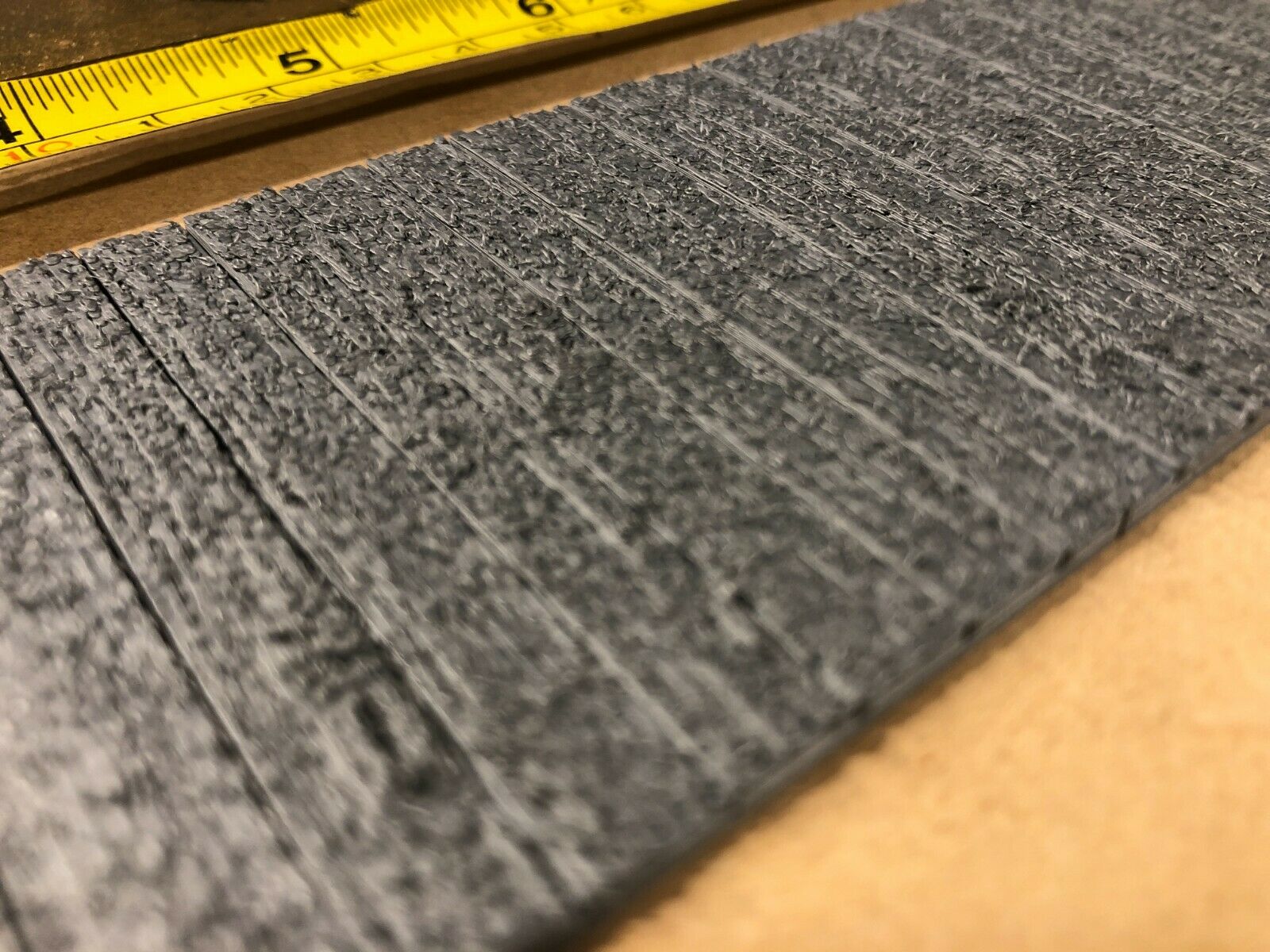

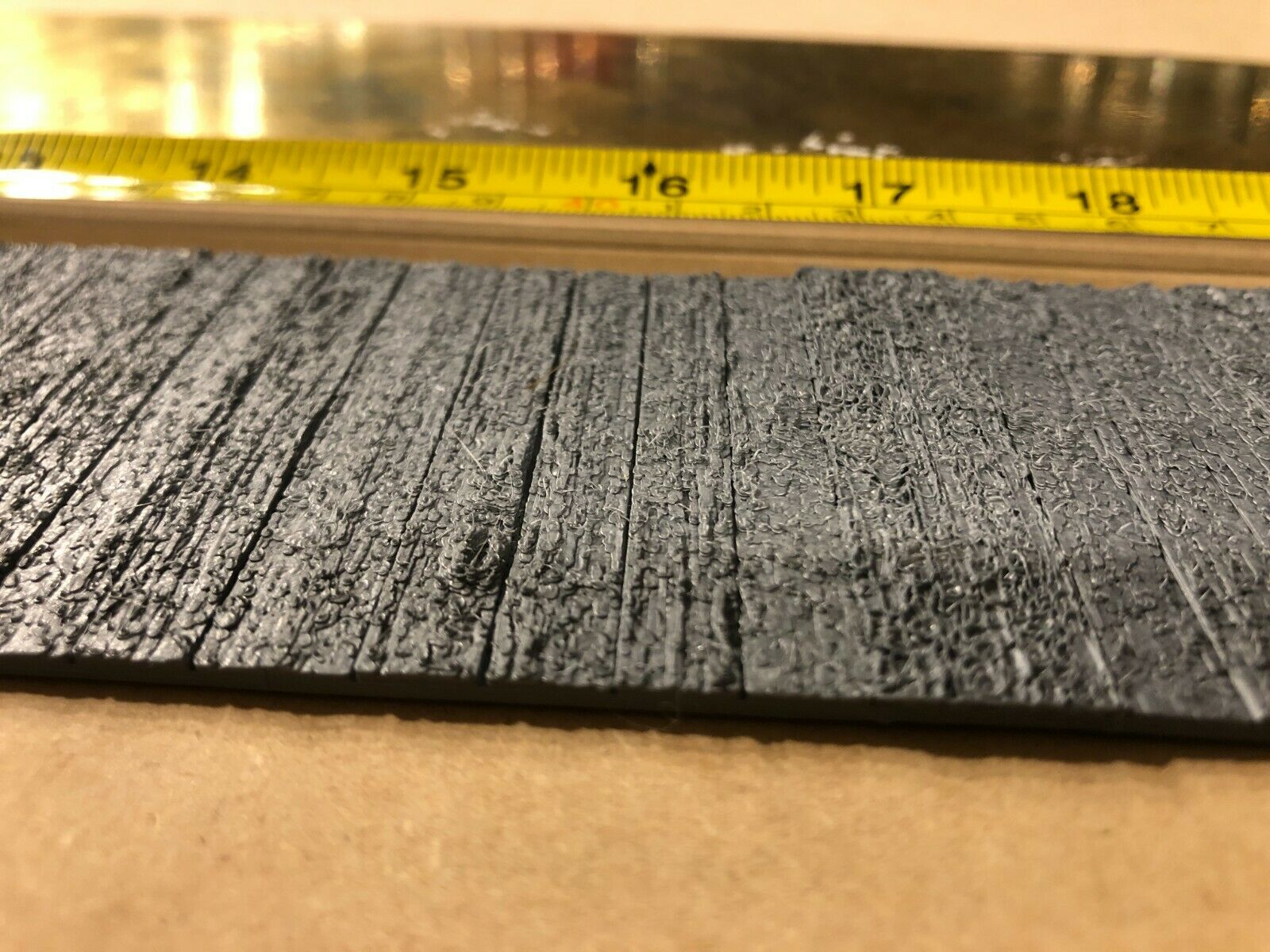

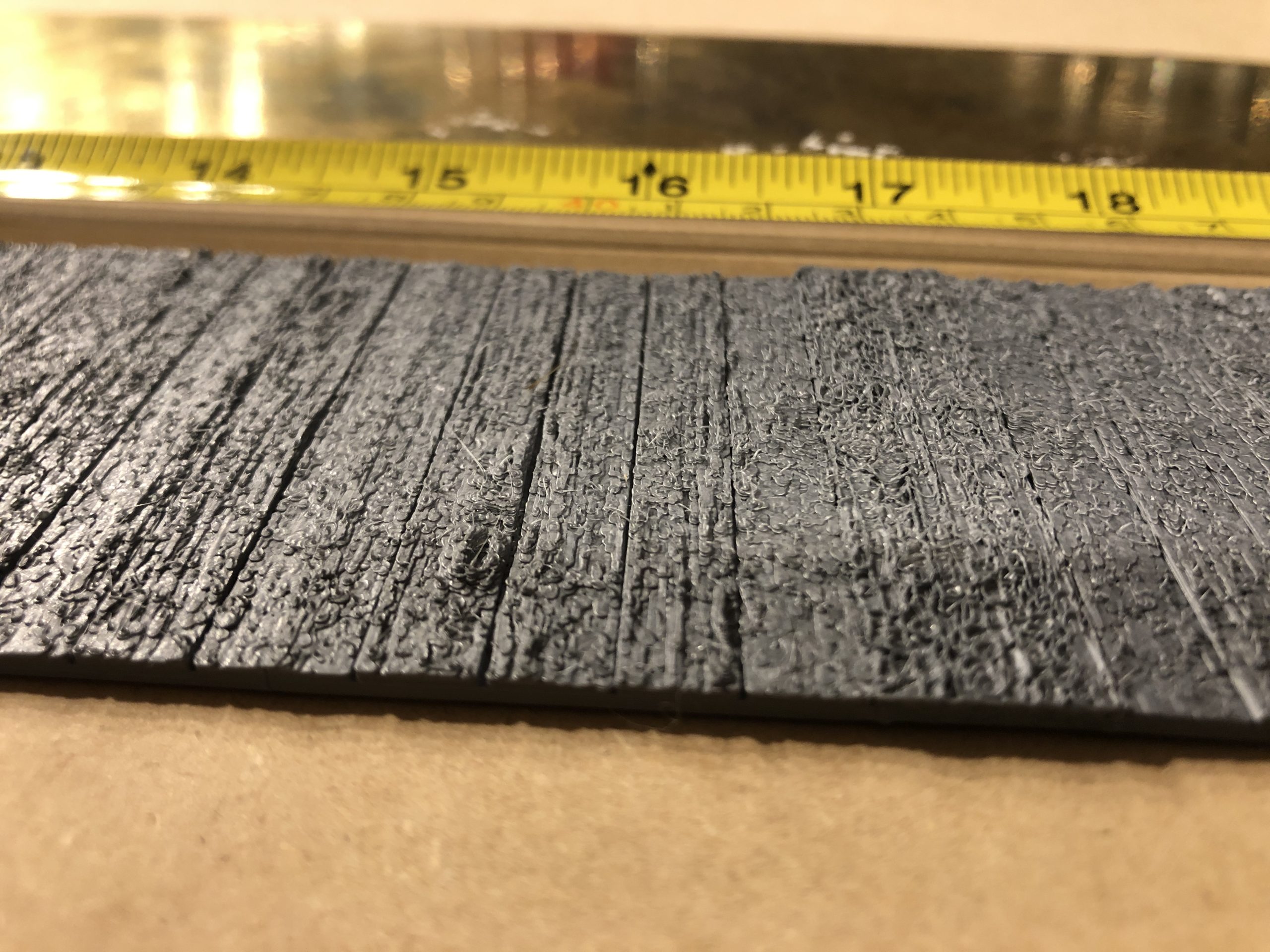

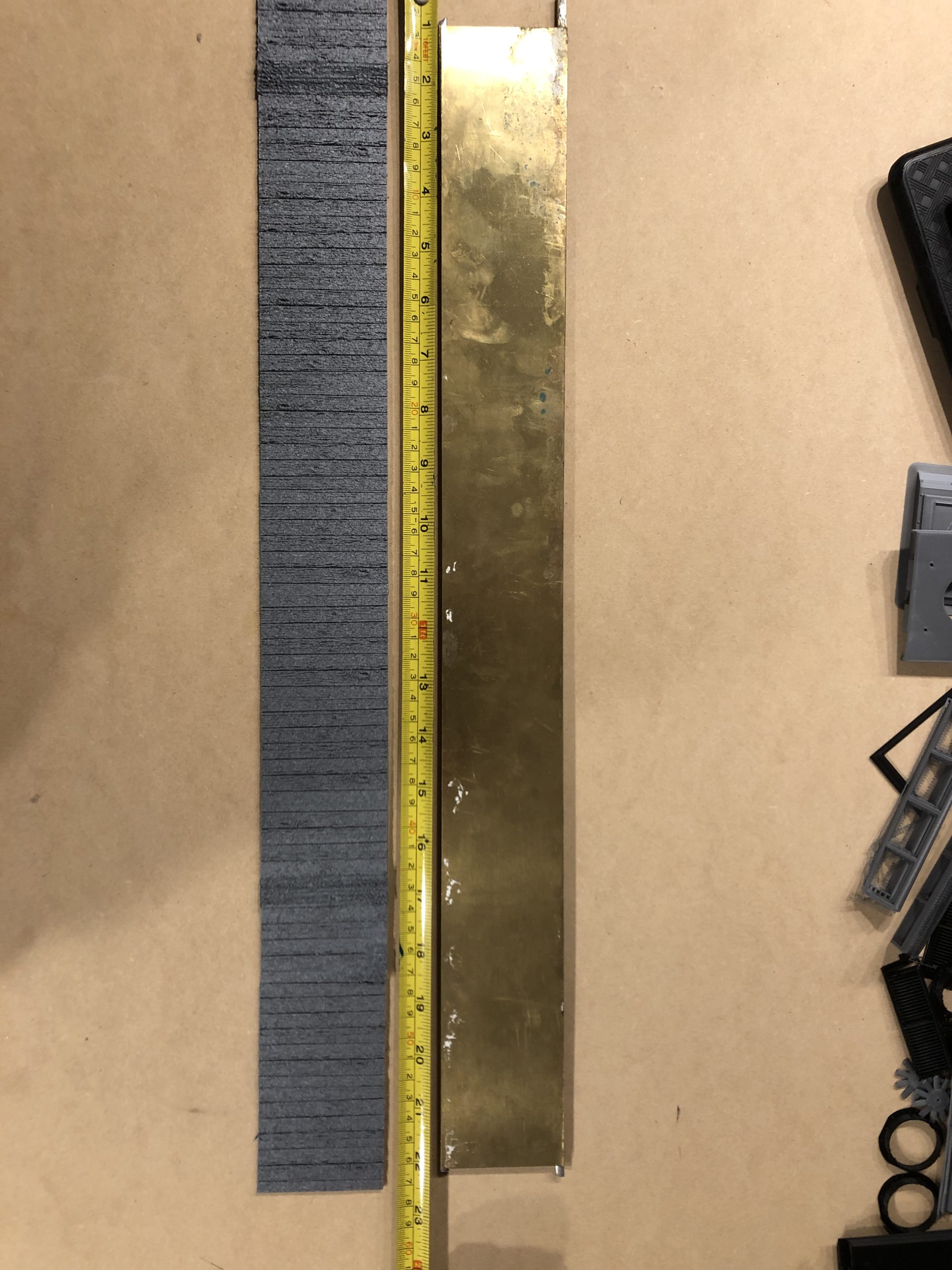

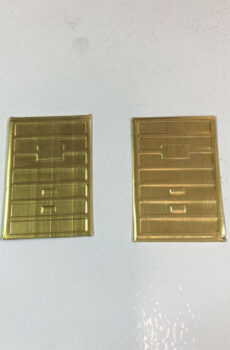

For Sale! Weathered and dirty timber decking 3D Printed for use to model realistic flooring in gondola cars, decking on flat cars or wooden timber ends on bulk head flat cars. Extremely close up photos illustrated the visual effect I wanted to achieve for or when viewing at a distance prior to any application of paint or artificial weathering techniques. My brass 89′ flat car is not for sale in these photos. The pieces are 60mm wide and approximately 3mm thick. I am shipping 3 longer pieces and but could be cut to make it flexible for use on cars of varying lengths. The plastic can be cut to a desired length and glued down in place.

As a craftsman and model builder, surfaces and in particular textured surfaces are everything. Over the years, I have tried with some success to emulate the realism of nature as well as man made surfaces with some okay results and mostly nothing to really impressive in my own opinion. Since my venture into 3D Printing I thought it would be possible to print various textured surfaces. As I found out it was pretty daunting task, at least for me. Having given up several times and coming back to it, I finally have been able to coax the printer into doing some interesting surfaces at scale. For scale model railroading in O Scale 2 Rail, many type of brick or stone work surfaces are desirable when building structures as well as wooden things like planks or fence boards.

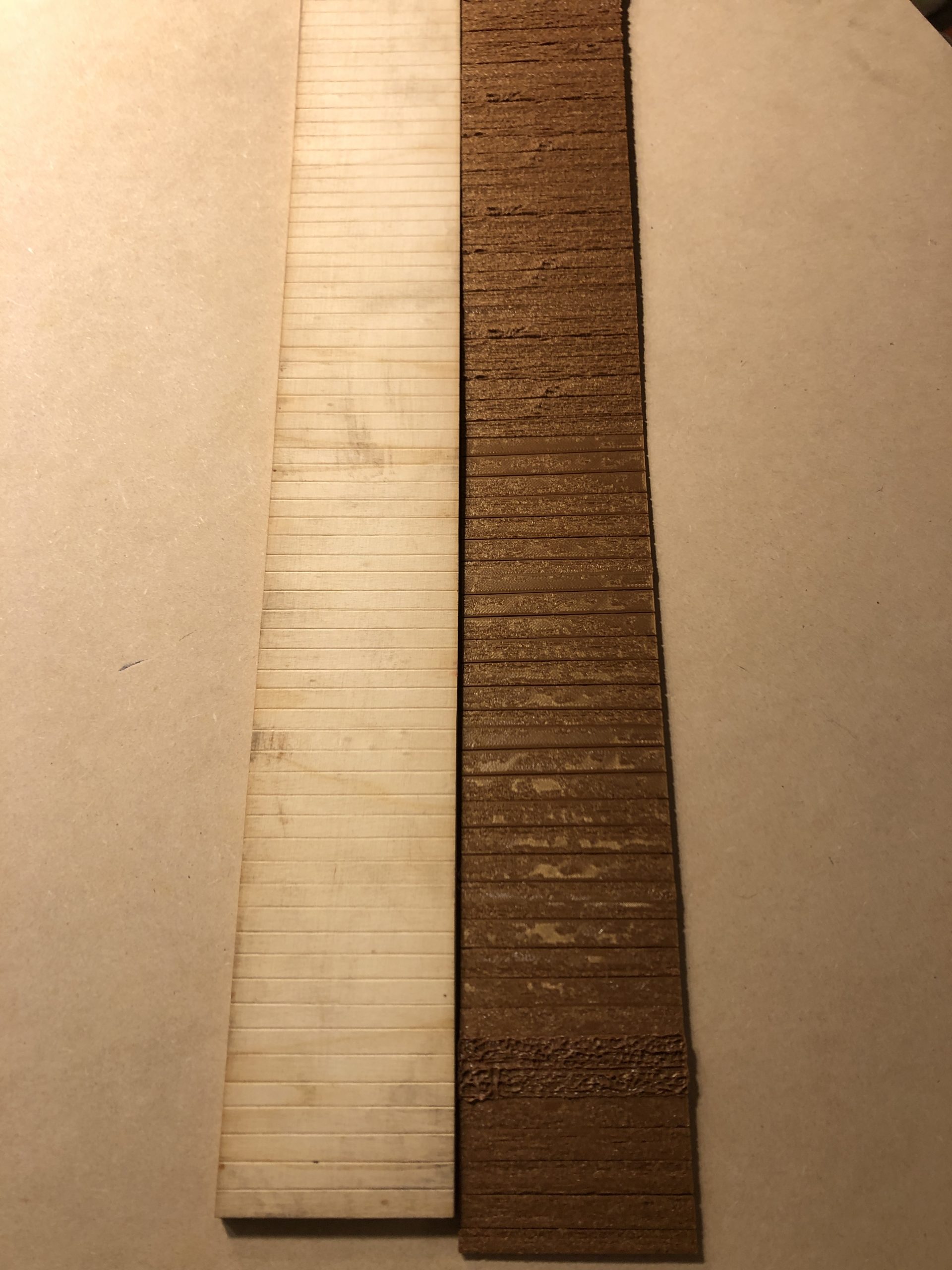

One of the things I wanted was to have wooden floors in my old gondola cars or on flat or bulk head cars. When the laser cutting or etching came to be, that was a vast improvement especially in terms of accuracy and looks. Almost to accurate and in some cases pattern unnatural in certain ways.

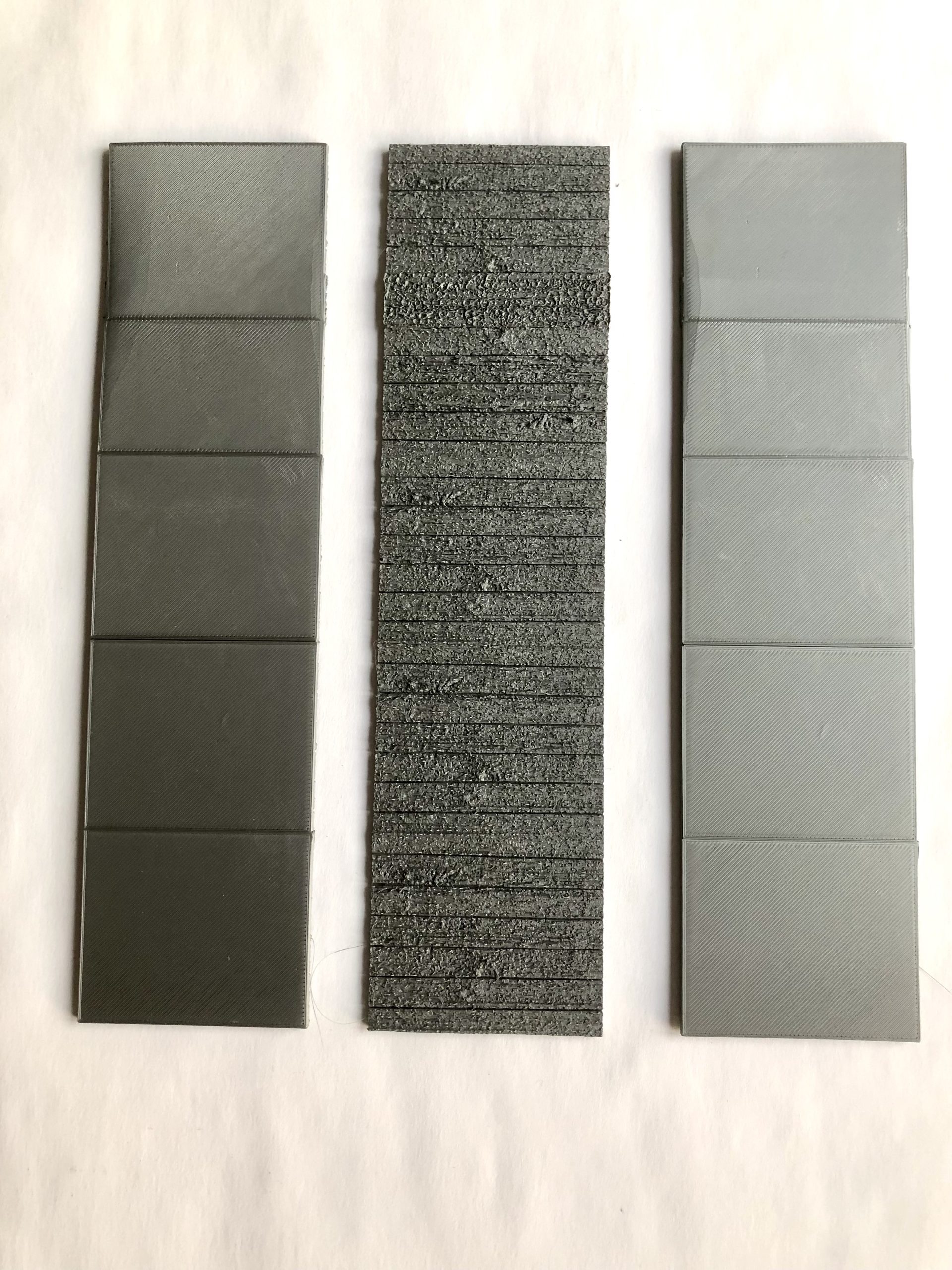

Though I have come to something that is satisfactory for my own personal modeling needs, it is less a solution and more of finding a random technique. Thus, I think my achievement is better than a laser production. The reason I say that is there are a few viewable aspects to evaluate that overcomes what lasers may not be capable of producing simply because they are removing material whereas the printer is an additive machine. The viewable aspects follow:

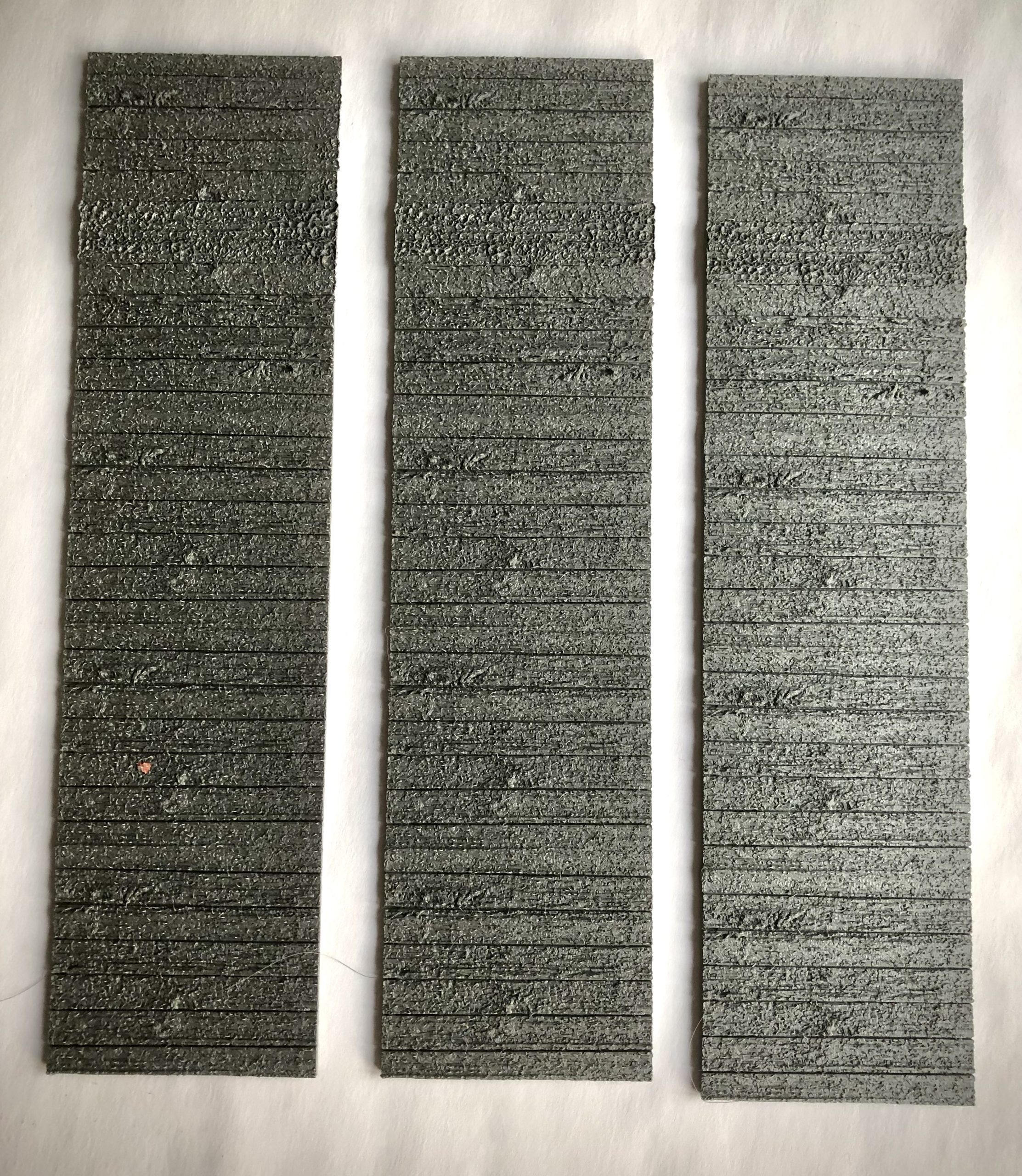

1. Looking straight down on a 89′ flat car with the wooden deck, one can actually see the wood grain on the timber and would be an aerial perspective.

2. The approximate width of a flat car deck is 60mm in O Scale. Viewing the deck at eye level from end to end, the timber as a viewable plain, due to the vehicle’s industrial use, the bed may have some wavy or unevenness to it similar to what you see in the prototype.

3. Angular viewing of said print not only shows the wood grain patterns or knots in the planks, I have some prints where you can also see the band saw lines when they milled the lumber. So if I am after weathered boards, the contrast is very evident even without using paint to artificially weather the surface.

4. Then there is perhaps an atmospheric perspective, meaning that viewing the finished print with no paint or artificial weathering, that is to say simply holding it up to the light at various angles or lighting effects on the layout, for certain textures the 3 dimensional aspects will jump out at you.

5. And finally linear perspective by looking down the length of the 89′ flat car not necessarily a true orthogonal vanishing point but just to see some type of detail where debris maybe pushing up from between the planks.

Given these considerations, it becomes hard to see any patterns that repeat, thus detail is more random as one would expect in nature or to a certain extend man made. Layers of slate rock might be a good example.

I am particularly please to be able to incorporate textured surfacing parts into a model or scenery on the layout through the use of the 3D printer as a tool. I can print stucco, all types of brick work, cobble stone, sheet metal to name a few. It is a lot of work and the print times can be very lengthy but in the end worth it to have made such progress where one gets the satisfaction that it brings to a finished model project.

PLA is not dishwasher safe and may deform in a hot automobile in the summer time as it has a relatively low glass-transition temperature.

Sold as is straight off the Prusa Printer built plate, all sales final no returns.

Made In The USA.