All Nation Line is introducing a new concept of 3D printed mock-up cars to develop higher standards for scratch building in brass. This prototype concept has never before been offered to the 2 Rail O Scale hobby.

One of the ways I typically go about building something from scratch is to first develop mock-ups in plastic, wood or card stock. This initial work proactively heads off mistakes and makes the process easier and more straightforward. It is like documenting and developing specifications prior to starting the project after having done the research on prototype specifications. This approach allows for a free flow of ideas as I think about refinements that will be necessary. In today’s world, 3D printing is an excellent tool to make the initial efforts more precise, faster and enjoyable.

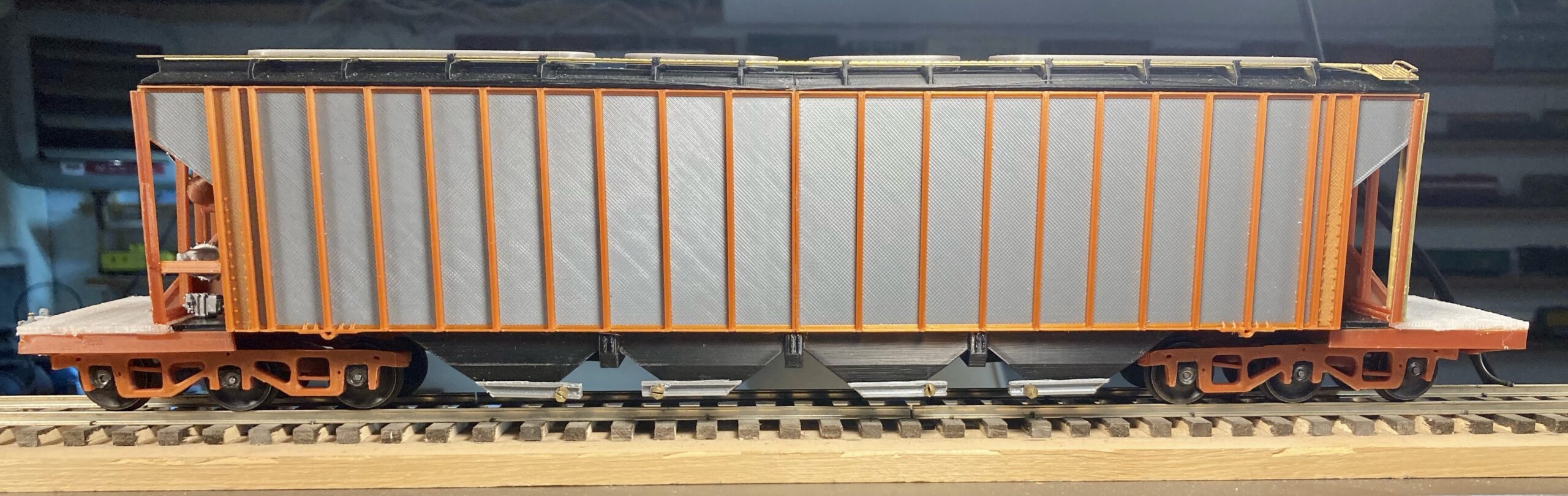

Consequently, The Atlantic Coast Line (ACL) one-of-a kind Whopper Hopper has been developed as a ready made 3D printed mock-up prototype car for your brass scratch build project. This mock-up provides an appreciable number of parts, patterns and stencils for the modeler. We chose this car because it is unique, and there is a wealth of photographs on the ACL/SCL Stainless Steel Whopper Hopper. In addition, this prototype toolbox includes several drawings as guidance. It is especially intriguing if a modeler wants to graduate from simply building pre-fabricated kits and step into the ideal world of brass scratch building.

So, in what ways is the Whopper Hopper unique? The car was manufactured by the Pullman-Standard Company. Only one of these was ever developed and manufactured. The capacity of the hopper was 135 tons. It was manufactured by a collaboration of several companies and suppliers such as using USS Tenelon Stainless Steel, 6 wheel trucks from American Steel Foundries, and various other components and hardware like the automated wash-out system, that all came together in Pullman-Standard’s Michigan City plant.

The 3D printed prototypical parts for this Whopper Hopper are meant to be used as the starting point to fabricate the basic super structures in brass. This preparation is required for assembling prior to detailing. As an example, you have the patterns to scribe the car sides in brass with rib positions and layout the hopper bay patterns as well as the roof. Using the 3D parts as the pattern for your brass is a great way to jump-start your scratch building project.

Using this method will be less costly in time and money if a minor error takes place during the build. The 3D parts can head off any inconsistencies such as an error or incorrect assumption made simply because of perspective on 3 dimensional angles. While developing a pattern part or even a work holding tool to be used in the construction, using online scale conversion calculators can be a very big help for verification of measurements.

Perhaps the main reason you procrastinate about getting into scratch building is the question, Where do I start? Prototyping is a prerequisite to commencing a scratch building project which ultimately saves time and allows for better accuracy and precision to scale. As an example, 3D printing a mock up of a 1906 Hicks Stock Car, in particular the ends on the car, will confirm the design or allow for making a refinement or fix prior to making the component in brass.

Why use brass? The answer to that question only comes after you have completed your first fully constructed brass freight car. Physically picking up a brass freight car, you can feel the massive stability and see the durability. A brass car’s impressive performance on the rails and its value surpass any ready-to-run plastic model. And then there is that intangible satisfaction that comes with the final preparation-painting and adding decals!

You may also choose to assemble the ACL Whopper Hopper prototype in parallel with the construction of the brass model, a digital twin, if you will. Making the leap from simple kit building to actual scratch building is not a trivial task; however, using this new approach you will acquire skills for your future scratch projects.

Perhaps now, your question about scratch building in brass, “Where do I start?” has been answered. This new approach using a 3D printed mock-up prototype of the Atlantic Coast Line (ACL) one-of-a kind Whopper Hopper will enable you to achieve a higher standard of workmanship and advance your skills when crafting your model O Scale trains.

All Nation Line is always available to help advise and guide you during the project. It is a good starting point for your next, or maybe your first brass scratch build!

Updated 5/31/2024: You can now check out “What’s New” Page for additional information on how you can purchase the Atlantic Coast Line (ACL) one-of-a kind Whopper Hopper 3D printed mock-up prototype car for your brass scratch build project.

Or just click here to review and purchase: All Nation Line Digital Twin Whopper Hopper Atlantic Coast Line (ACL) 3D Printed Mock-Up Prototype For Brass Scratch Build PN#1929AN

Enjoy! John Wubbel

Another way to look at this product is to visualize its 3 Dimensional “Digital Twin” – Atlantic Coast Line Whopper Hopper No. 500000 CLASS L-12 rendering via the 360 degree technology to see it from all different angles! Below, The Easy 3D Viewer menu allows you to manipulate the image to study it in closer detail.

All rights are reserved for model photographs, drawings, CAD, renderings, files, printed parts, blueprints, etc. are copyright, property of The All-Nation Line and may not be used for commercial reproduction by 3rd parties without specific license agreements.