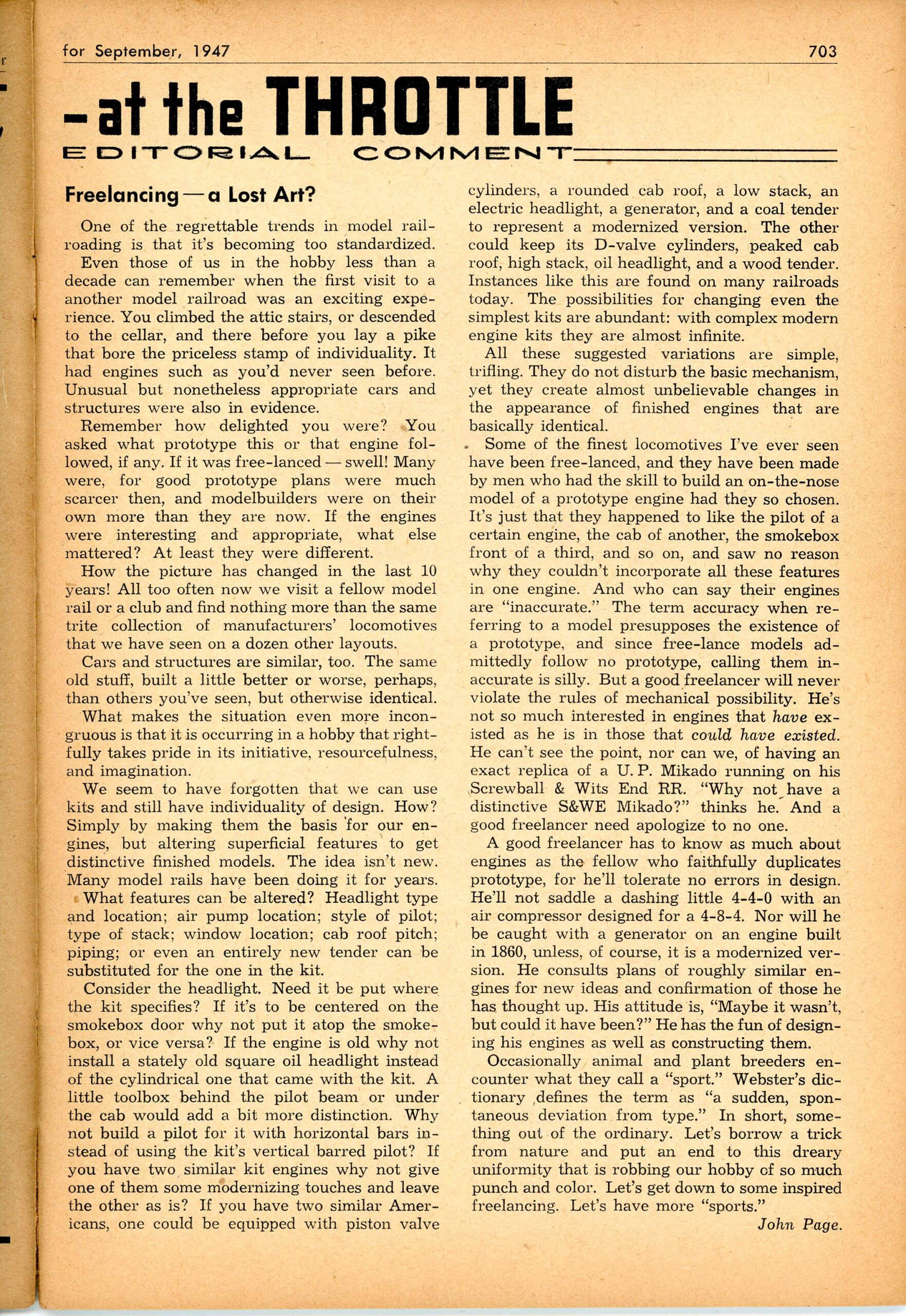

Freelancing: In the September 1947 issue of Model Railroader on page 703, John Page wrote an editorial comment in the column “at the THROTTLE” titled “Freelancing – A Lost Art?. Written 77 years ago, the question remains the same today in our hobby. The gist of the editorial is around the fact that all to often when we visit a fellow model rail or a club one finds nothing more than the same trite collection of manufacturers’ locomotives, ready to run rolling stock etc., that we have seen on dozens of other layouts. However, over the years in my experience, some of the most memorable or even celebrated model rail layouts have been the freelancers. John Allen -Gorre & Daphetid, John Armstrong –Canadaigua Southern, Frank Ellison –O Scale Delta Lines, Bob Hegge –Crooked Mountain Lines, Lorell Joiner –Great Southern Railroad, and current day David Stewart -Appalachian & Ohio Railroad have been profound influencers and inspirations in our hobby, including Miniatur Wunderland, where modeling to standards is mixed with free lance creations, making for a delightful visit.

The historical path of model building, i.e., doing it from scratch to craftsman kits to manufactured ready-to-run (rtr) out-of-the box models, has made it easy to get started in the hobby. RTR typically leaves me wanting more out of the hobby after a short while. Even the dedication to fidelity in Proto48 model building to specific roads and equipment does not fall into the category of free-lance model building but that does not mean in P48 one can’t take a sudden or spontaneous deviation from a fixed type specification and, in short, borrow to model some tricks to put an end to the dreary uniformity of standardization. Perhaps the notion of free lance model railroading is fundamentally more contagious today within the traction or narrow gauge communities, as for example, a logging road that was more or less dictated by geography in order to get timber to market.

Our hobby of model railroading rightfully takes pride in its initiative, resourcefulness, and imagination, so why not free lance? Even if it is only a tiny scene on our layout, give it a try.

Imagineering

What’s in Naming Your Railroad?

The All-Nation Line Railroad

The All-Nation Railway Line

The All-Nation Line RailNet – Serving the Globe

The Flat Stack Railroad Car

The imaginary All-Nation Line Railroad owns 12,232 container flat cars transporting loads nationwide as dedicated unit trains. Specializing in logistics for optimized delivery to shippers and customers alike, the ultimate optimization and utilization was achieved right after piggyback services came into being as a Chicago Great Western (CGW) innovation. Today, the entire consist of flat cars have been standardize to enhance further innovation by the company.

Like every rail transportation company, freight cars are not earning revenue without a load. Therefore, if sitting idle in a yard, in storage for any period, or empties are sitting in the Midwest when they are needed on the West Coast, it is a problem. In order to get a string of flat cars with no containers from Chicago to LA, it was not uncommon to see a 2-mile-long priority train sailing across Iowa with 3 motors on the front end and 1 in the middle or end of the train pushing the speed limits.

The Flat Stack Cars in the fleet came into being as a solution to optimize this pipeline problem. The result was a drastic reduction in empty transport costs. The key was to standardize the construction of the car such that the railroad could split the train in half and use the Rack Stacker Ramp to load an empty string of flat stack container cars as a layer-by-layer deposition, i.e., the lower layer supporting the upper layer of empty flat cars.

The key feature of the flat stack car comes in a standard 89′ length, light rail head integrated into the car’s bed, automatic adjustable wheel air brake clamps, automated retractable bridge plates between car couplings, and the Rack Stacker Ramp, a rise-over-run means of quickly loading the empties on top of the lower layer of flat cars. The Rack Stacker Ramp can be in tow to any location to offload or load another set of cars.

Key advantages:

- Less locomotive power required to move the same number of cars to any destination

- Shorter trains that tie up railroad crossings

- Can conceivably take up less yard space when cars not in use or are idle for short durations

- Better use of shorter passing sidings to improve upon means of decreased congestion

- Flat Stack Cars with low profile containers can be stacked on top of a set of empty lower layer of cars

- Can transport non-standard flat cars as an upper layer, such as well hole, spine cars, articulated spine cars, etc

- Can earn revenue from other roads that hire All-Nation to transport their empty flat car equipment

- Increased Stacked Long-term rail car storage rents using less yard real estate

- Rent revenue charged for use by other railroads

- Inspection drones are used throughout the load/unload process using digital twin and AI technologies to insure mechanical and safety features thus reducing manpower using pre-programmed flight paths

Key disadvantage:

- Standardized Stack Flat Cars are currently not available for interchange

- Cars must remain as a unit

- Licensing and training certification of personnel on other railroad operations required

Rack Stacker Ramp

The gradient or slope of the line from the rail head to the bed of the first receiving lower layer car can be calculated by the following basic math:

From Two Points: The points on the line are used to find rise over run of the given line. For any two given points (x1,y1), and (x2,y2), the difference of the y – coordinates y2−y1 represent the rise, and the difference of the x-coordinate x2−x1

represent the run. The rise over run can be calculated using the following formula.

Rise Over Run = m = (y2−y1)(x2−x1)

Angle Made By The Line: The angle made by a line with the positive x-axis in the anticlockwise direction, θ is useful to find the rise over run of the given line. The tan of the angle θ is used to compute the rise over run of the line.

Rise Over Run = m = Tanθ

The rail head end of the ramp is an aligned set of points that interface from rail head zero to its hinged point on a single 22” wheel set. The car loading end of the ramp is a coupled interface on a single 33” wheel set with bed height pneumatically adjustable locked in place while loading. The ramp can be unlocked and remain coupled for towing to the next unloading location.

Secondary loading facilities are available for bed level loading/unloading at all yard properties of the All-Nation Line Railroad. Rapid racking of empty flat cars was a key innovation factor in turning around equipment to quickly transport them where needed anywhere in the country. However, applied logistics algorithms can be applied for pre-sorting cars before loading. So in other words, if a section of flat cars needs to be dropped off, in Denver on the way to LA, they can be pulled off and the consist continues onto its final destination.

The transportation savings cost has to do with fewer wheels rolling on the rail head or reduced axle counts, less friction, reduced horse power required to move the same amount of equipment. In other words, the railroad is getting more work out of the motive power available and a reduced fuel bill. Some key aspects of this innovation are proprietary and remain undisclosed. While All-Nation patents are on file, testing and performance data that results in its governance remains undisclosed. Obvious operational and configuration procedures such as the use of a loading mule or switcher engine are used to push and stack the flat cars or for off-loading.

Competitive advantage:

- Reduced revenue down time for load free equipment

- More equipment rapidly spotted for shippers

- Empty low profile shipping containers can be loaded as the upper layer and still be within over the road clearance specifications

- Availability and utilization options competitors cannot replicate

Imagine That! Model Railroading Is Fun!