Description

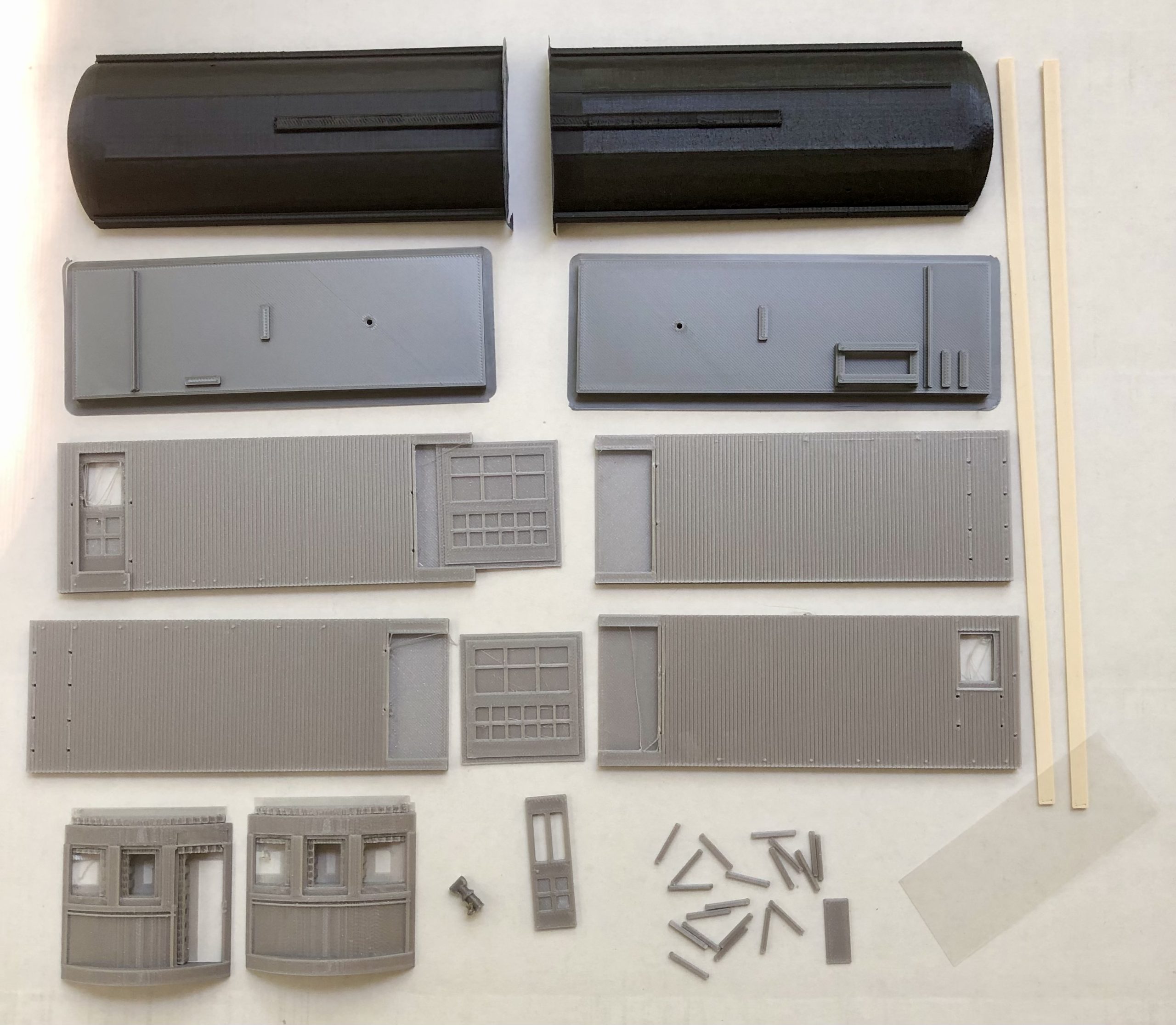

The All-Nation Line C&LE Box Freight Car Traction Kit PN#11K

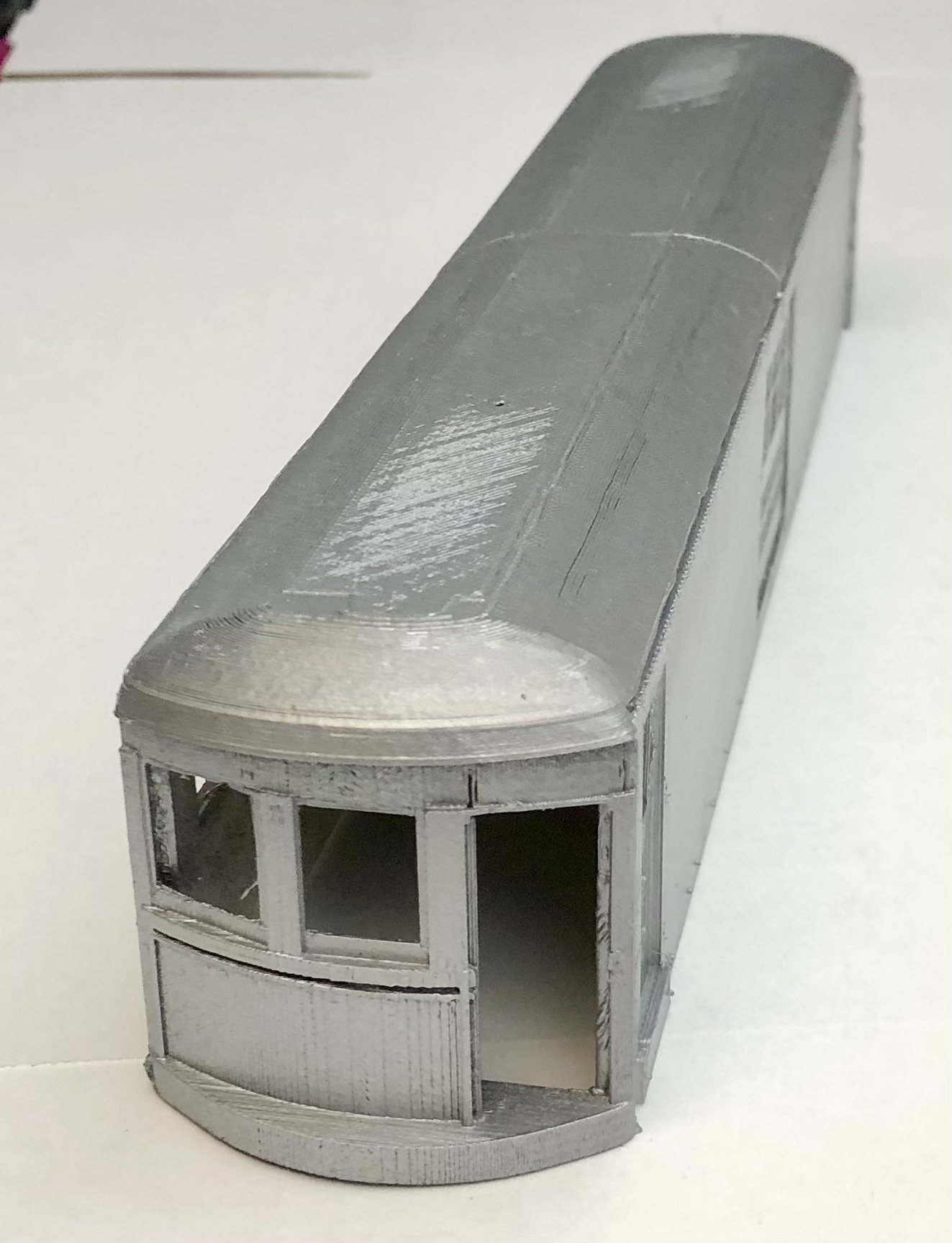

This purchase is a kit. Assembled photos are for reference only.

For Sale: The Cincinnati & Lake Erie Railroad (C&LE) kit. Courtesy of the members of the Bay State Model Railroad Museum and Model Railroad Club, (WWW.BSMRM.ORG) members and particularly Charlie Pitts provided a scratch built reference model upon which this kit has been designed. Once again, AN is of the opinion that provisioning an easy to build kit for new O Scale modelers and entry level builders is a great way to attract many to quarter inch scale model railroading. And one of the most interesting scenes is freight interchange between traction companies and the railroads.

The kit is only the basic shell and requires the modeler after assembly to finish up the model with the appropriate hardware details, thus is an entry point or introduction to scratch building without starting from scratch. The kit should also be challenging enough for the beginner to learn about and research on how to glue and finish parts and surfaces on 3D Printed body parts consisting of differing plastics. See the following links for

The Great Guide to Gluing and Assembling 3D Prints

The parts in this kit are ready for postprocessing and the following article is a great instruction on how to go about putting the finishing touches on the model.

Postprocessing of 3D prints step-by-step

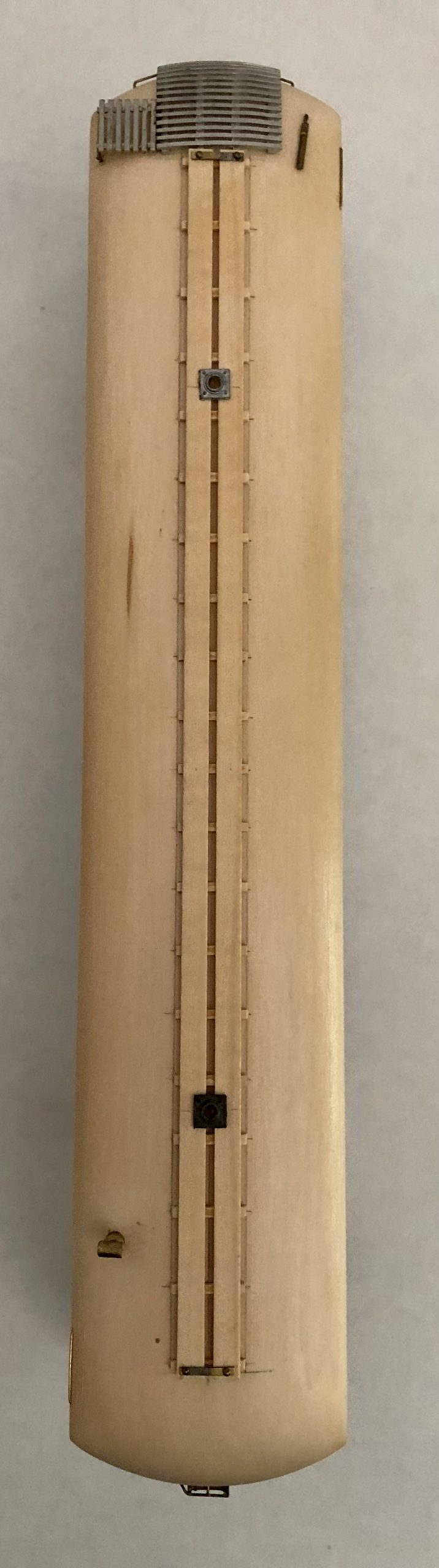

As mentioned above, this is a basic kit in its simplest form, a shell of a body. The reason is it gives the modeler many options. First, research into the history of these cars of various configurations on this railroad. The modeler may prefer to tailor the car to a particular prototype can such as the 640 located at the Illinois Railway Museum. Second, the modeler can opt to glue up a solid body or optionally configure so either the floor or the roof can be removed for servicing if this is going to be more than just a shelf model.

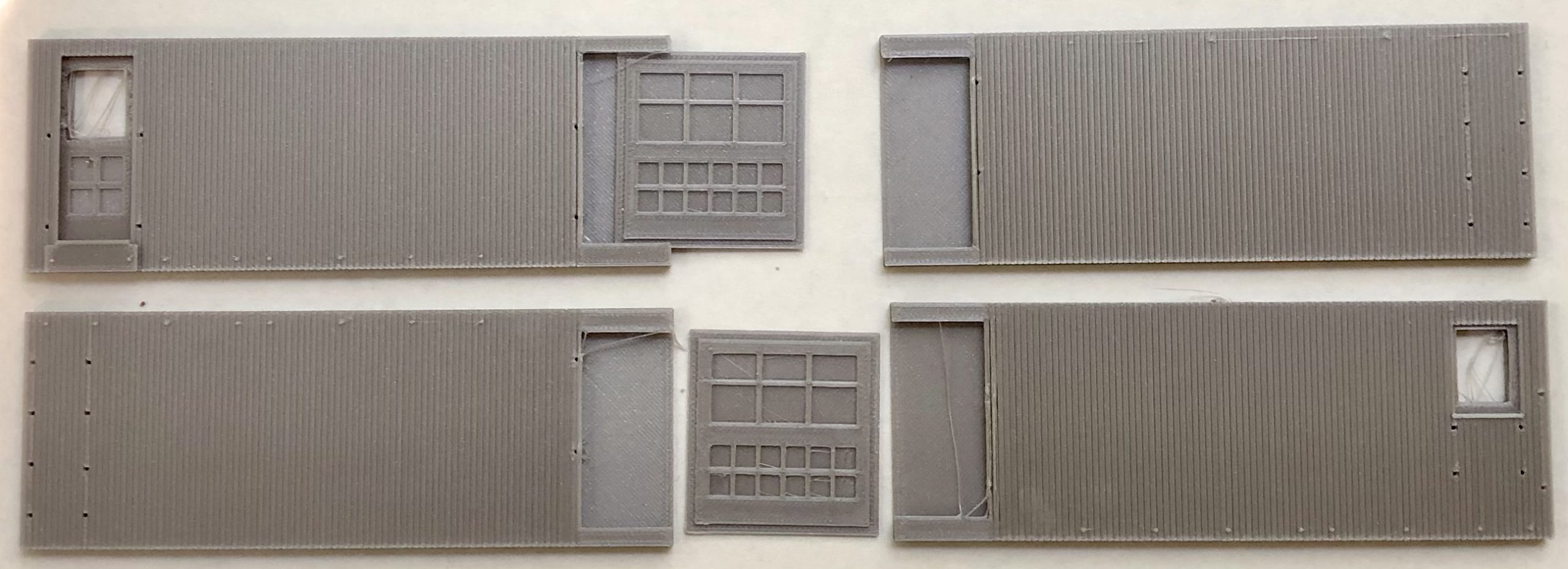

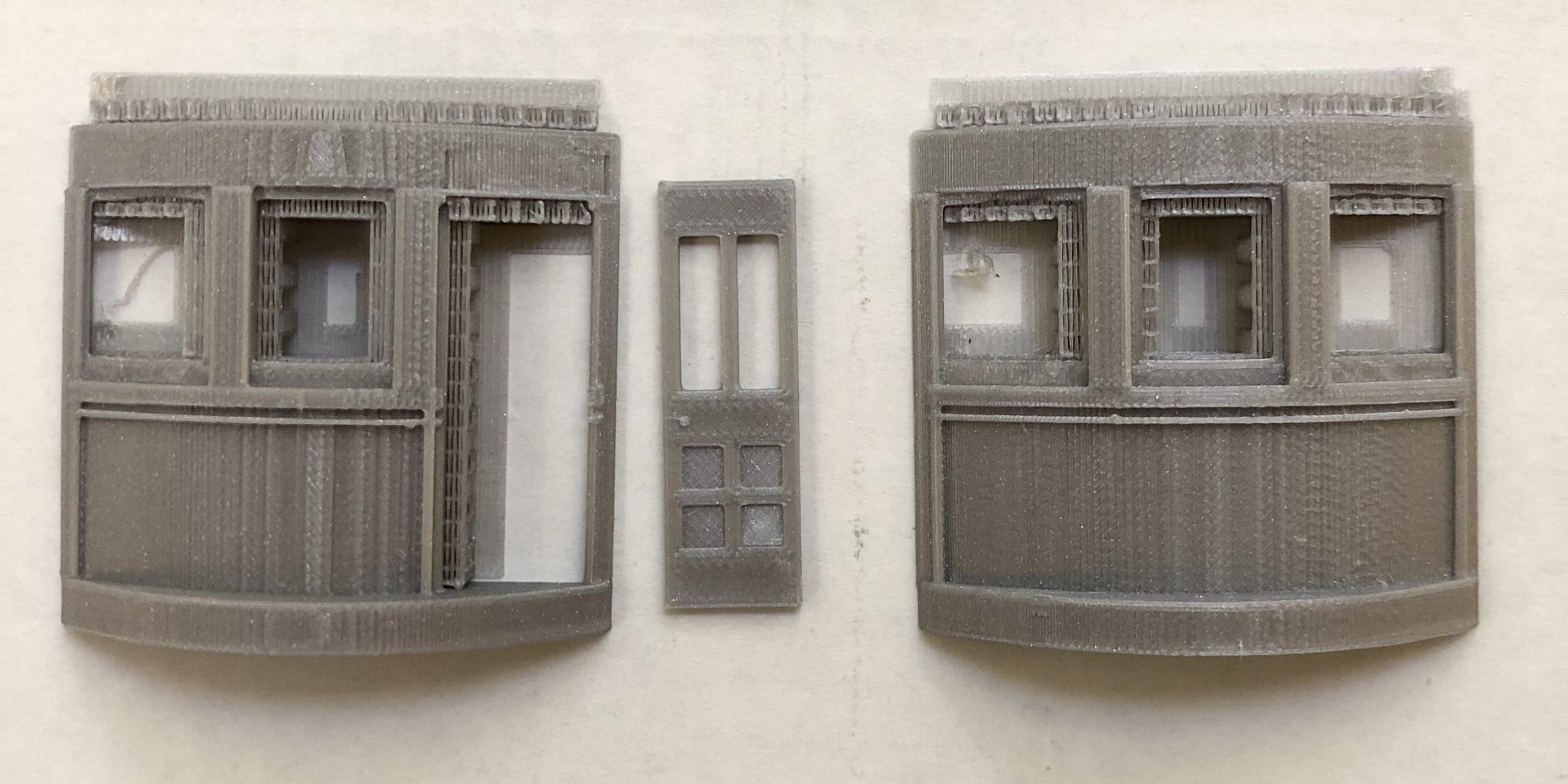

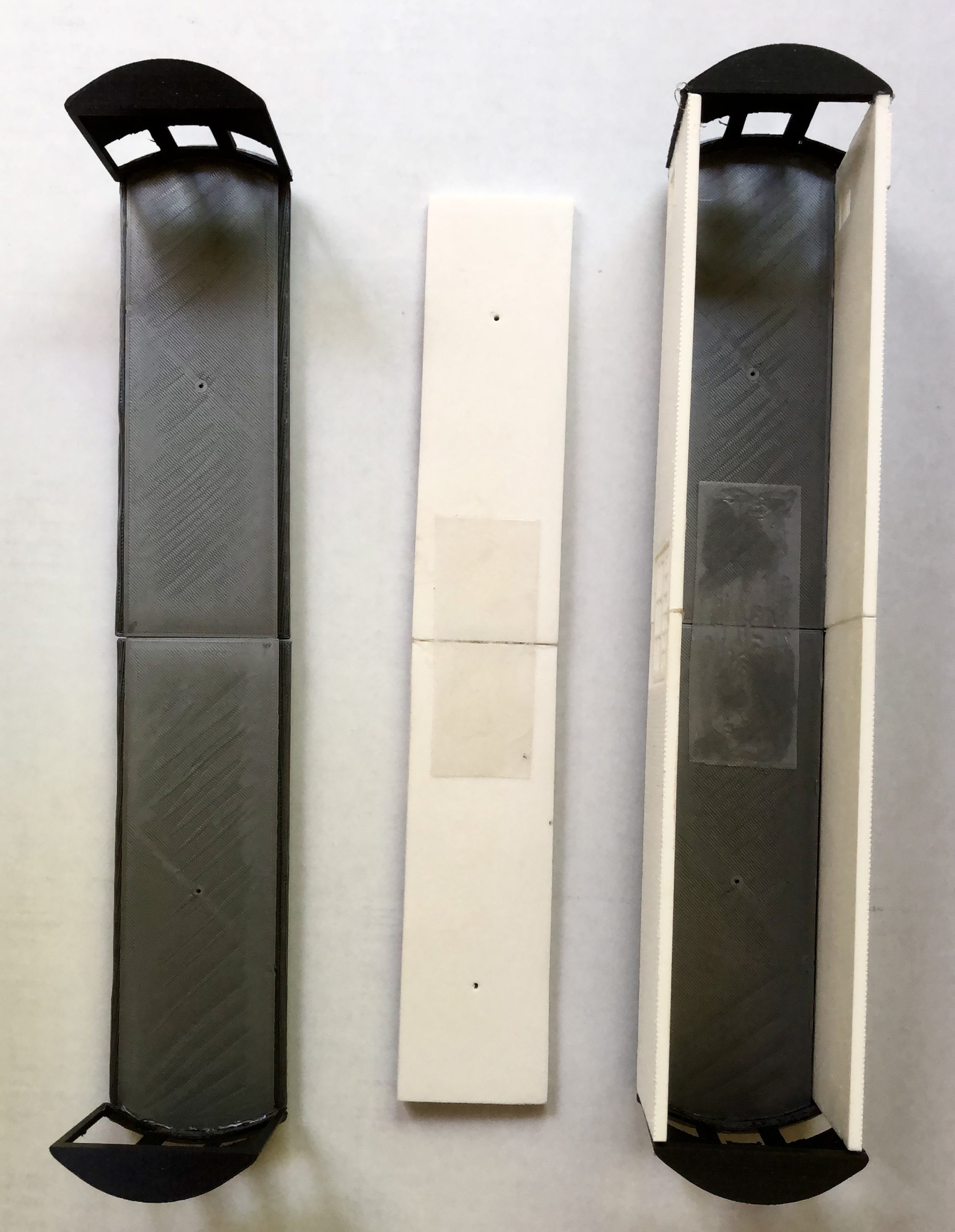

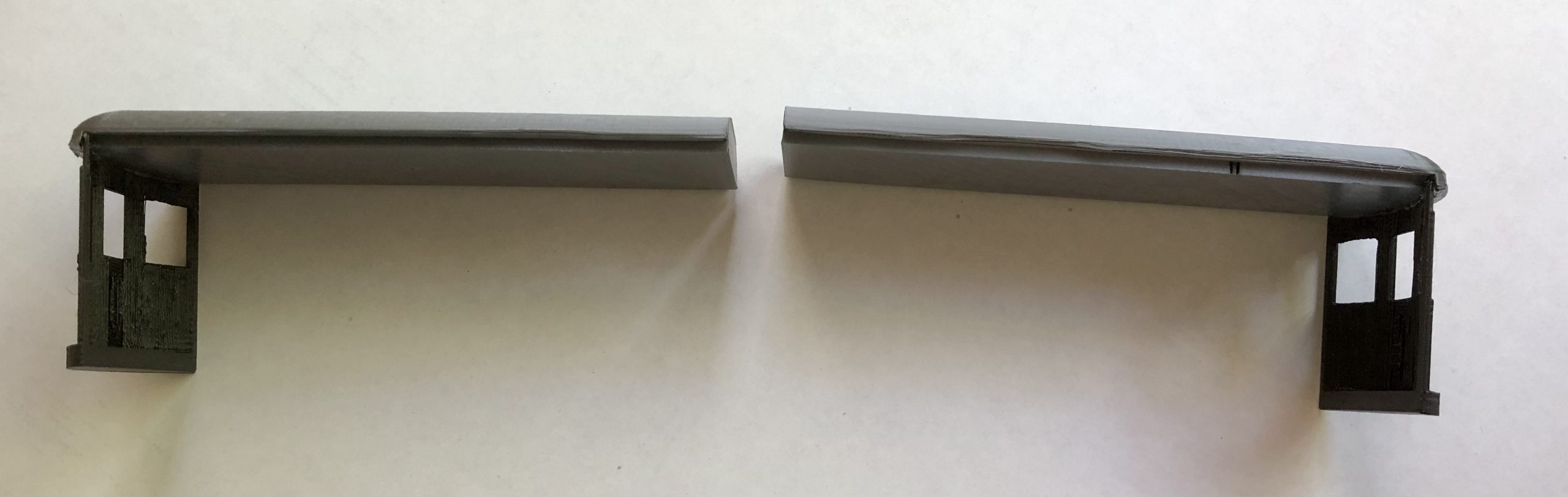

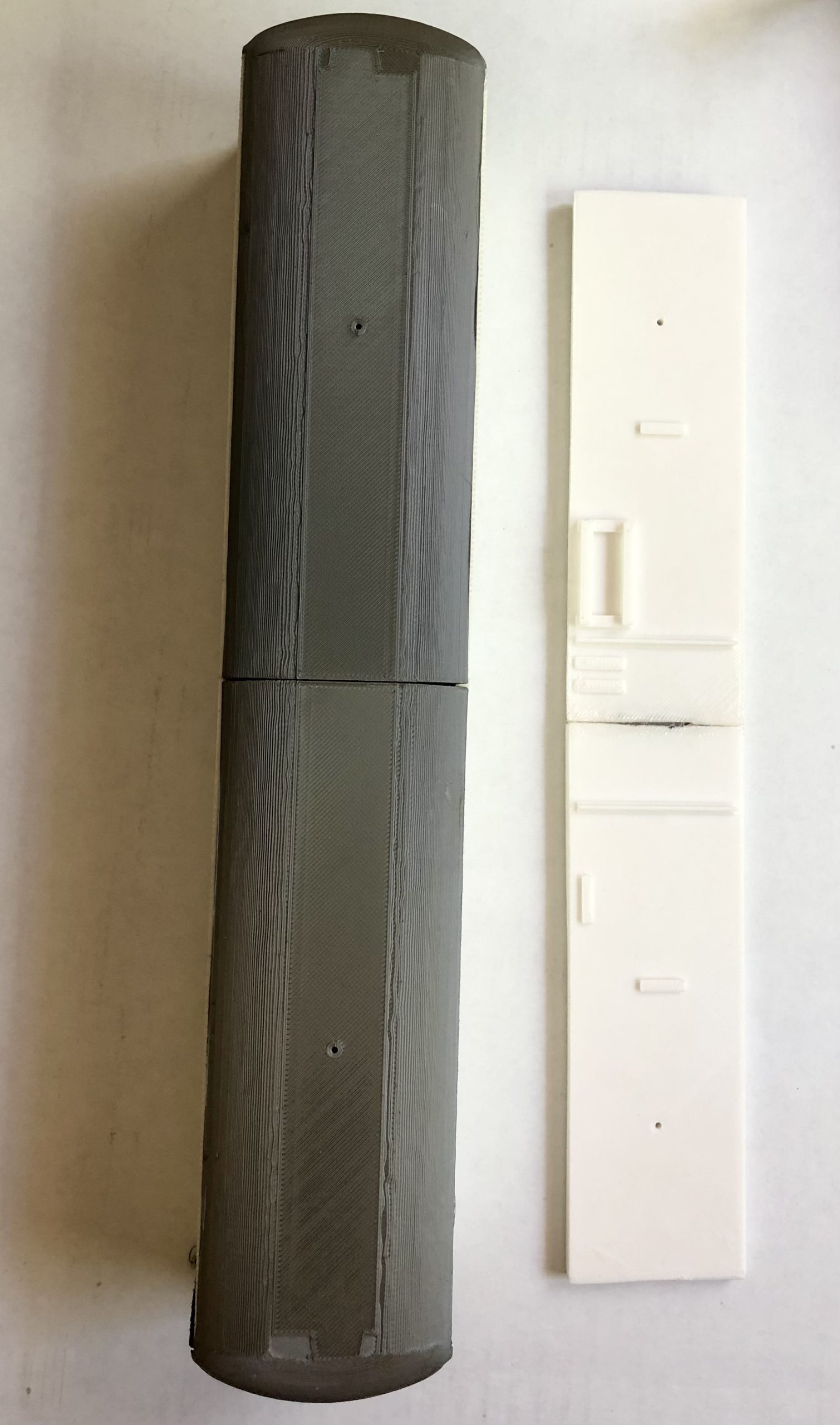

The roof comes in 2 pieces as do the sides and floors that must be glued together. The roof is a solid 100% Infill ABS plastic and can be finished to an ultra smooth surface. See one of my techniques for surface smoothing in this video: https://johnwubbel.com/crh/Brass-Investments-Project-Web-Show/C&LE+Postprocessing+Video.mp4

In gluing up the parts, make sure everything is perfectly square. Any glue seams or joints can be filled in with a little polyester resin and sanded. The floor is also ABS plastic while the car sides and ends are PLA plastic. I typically use a CA glue or Loctite Extreme Glue of a little thicker consistency. However, our prints are getting extremely smooth and detailed now with advances in the software that supports FDM printers. In any case, I am turning more to J.B. Weld Kwik for plastics body work on my models.

The C&LE kit was modeled in the FreeCAD software. The roof was particularly challenging because of the variable radial roof ends. In order to get the best representation of the prototype, the surface modeling in 3 dimensions had to be done with the Non-uniform rational basis spline (NURBS) mathematical model using basis splines (B-splines) that is commonly used in computer graphics for representing curves and surfaces. It offers great flexibility and precision for handling both analytic (defined by common mathematical formulae) and modeled shapes.

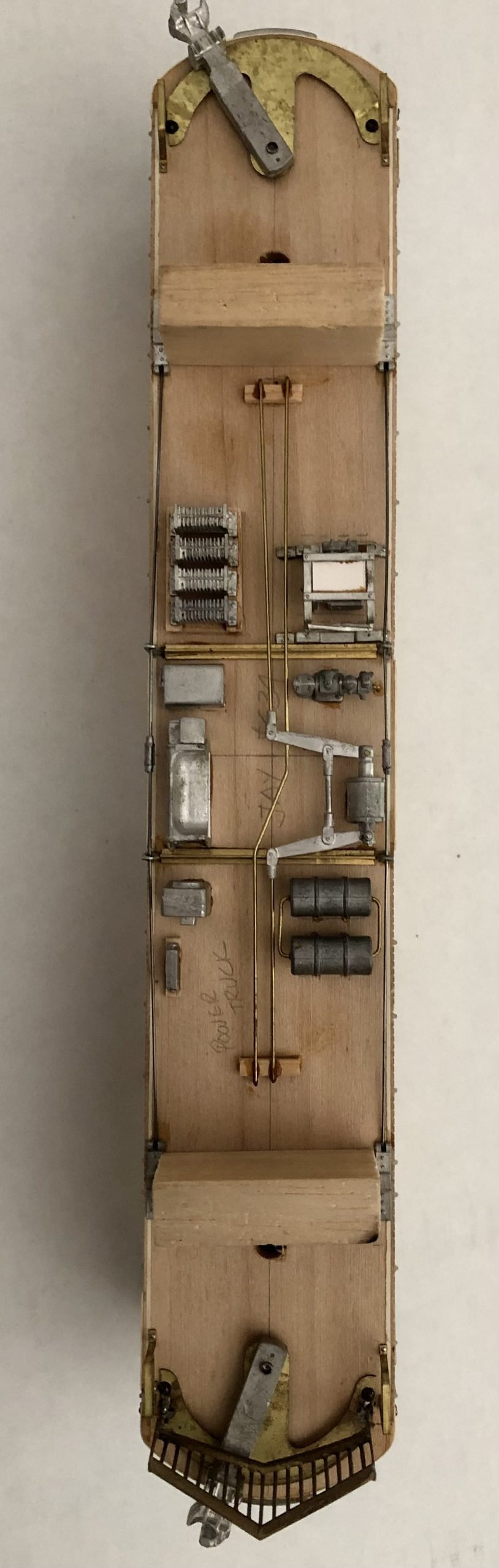

The modeler will have to do some 3D Print cleanup of plastic build plate support structure material before assembly to fit the parts by hand. For example, the car ends fit into an arc slot in the underside of the roof. Consequently, the slot will need the modeler to remove the material if it does not drop out on its own. There is 1 wafer to be used to glue the 2 floor sections together and slots for the window panes in the car sides that might need a little clearance of threads to slide the acetate window glazing in. If the PLA is drilled, a sharp drill bit and going very slow so as to not heat the tip of the bit is recommended. ABS drills the best and also taps well. The roof walk planks may be substituted for real wood stripes if so desired. The underside of the floor has all the mount points printed for car mechanical details. Detailed photos of the reference model are online to guide the modeler for learning purposes from a master builder which is very evident such as the trim under the eve of the roof.

We hope you enjoy building out this unique interurban kit for your O Scale Traction layout.

Printed parts may be in different colors other than seen in the photos. Sold as is straight off the Prusa Printer build plate, all sales final no returns. PLA is not dishwasher safe and may deform in a hot automobile in the summer time as it has a relatively low glass-transition temperature between 50 and 80 °C and a melting temperature between 170 and 180 °C

Made in the USA