Description

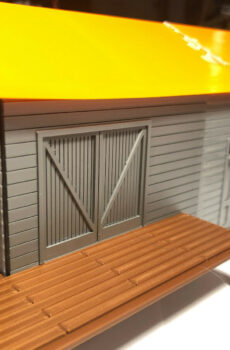

A number of O Scalers have been working to study and redevelop/improve upon a specification for building module sections for running trains at the many Train Shows around the country. Part of this work was in developing components and parts to make it easier for modelers to quickly assemble a section, put track on the table top and take to a show to join it to other modules for a really large running layout. Consequently, we came up with a number of parts that cannot be sourced anywhere so we engineered them for 3D Printing. As an O Scale Kings project, once the specification is finalized, we will make the files Open Source and freely available. In the meantime, for modelers that do not do 3D Printing, I will try to make these accessory items available on Ebay.

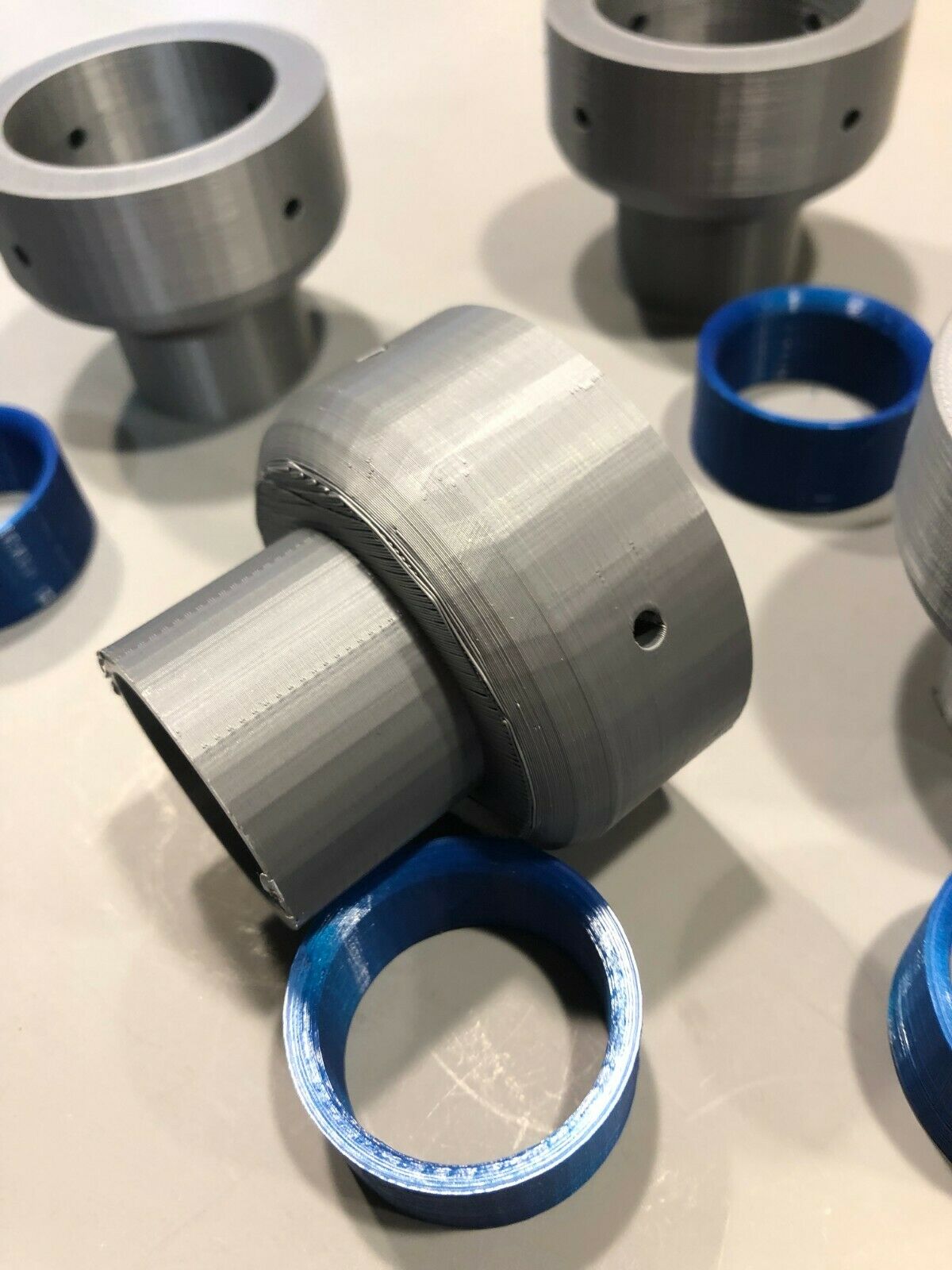

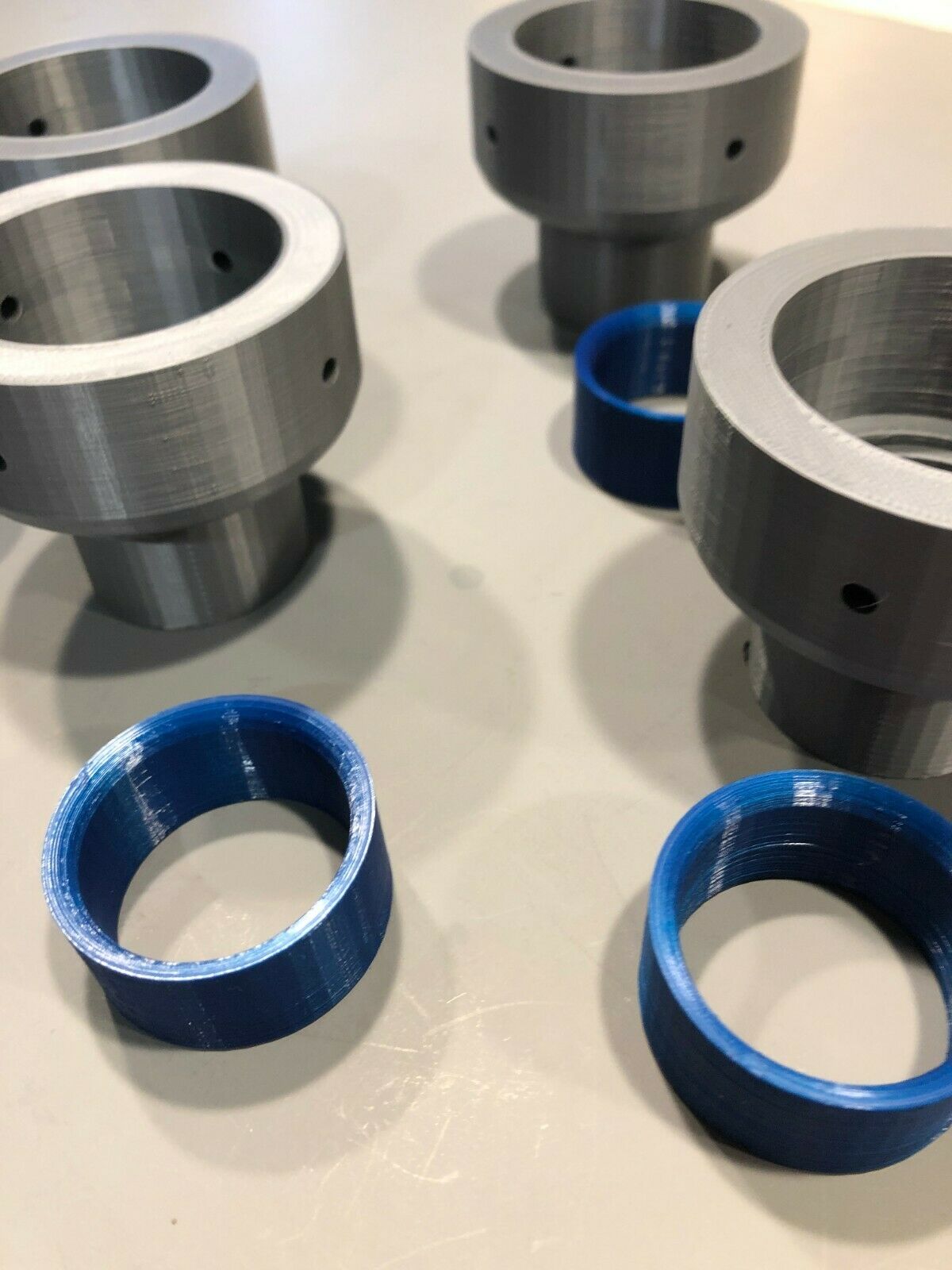

One of our cost reduction efforts involved allowing the PVC options in regards to the legs. We know that modelers do not have adequate wood working shops, so we developed the PVC telescoping legs so that the table height can be range adjusted for 40″ or 50″ heights. The upper main leg part (30″ 1 1/2″ PVC), to facilitate a 1 1/2″ PVC leg section and the 1″ PVC that slides within the 1 1/2″ are 4 Telescoping Reducer Leg Connections/Couplers consisting of 4 inner support rings that go inside the 1 1/2″ pvcs and 4 the couplers that make telescoping possible. We wanted strength yet keep the legs as lite weight as possible. Thus for one table, 2 pieces of pvc of each size to be purchased in 10′ lengths, should be cut to lengths of 30″ each. If so desired, the large end of the coupler can be permanently mounted to the 1 1/2″ pvc with 4 brass countersunk 1/2″ 6-32 screws drilled and tapped into the pvpc. Leg foot pads, bracing rings and optional robust leg floor levelers are available in a separate listing. We also developed the large corners to accommodate the PVC legs as it would be an integrated component to the table top frame.

The inner rings that go inside the 1 1/2″ PVC must be slightly sanded with a large grid paper and hand fitted. The tolerance to the inside diameter of the PVC is very close and what you want is a snug fit so that glue or screws are not require. Note the chamfer on the inside on one end of the ring. The ring should be directed downward from the top of the leg with chamfer facing the floor and driven with a stick or wood doll 20″ as this gives the smaller 1″ PVC interstitial space support as the 1″ is adjusted to various heights. The chamfer lets the 1″ pvc tunnel into the ring without any resistance.

The goal was to make it easy for any modeler to build a modular section to participate running trains at a train show such that quick set up and tear down would be an incentive along with easing the effort to avoid building it from scratch and sourcing materials. Thus, for the frame a pine 1×4 for the sides cut to length at Lowes or Home Depot, a 1×4 hard wood for the ends cut to length for the table width, PVC, a piece of homasote or GoBoard + a sheet of Luan for the top, the only thing left to source at the local hardware store would be some 10-24 machine threaded screws with wing nuts. For bracing if needed with the rings, some 6′ aluminum bar stock cut to length maybe required for a 50″ table height for added stability.

Printed with Prusa PLA filament sold as is straight off the Prusa Printer build plate, all sales final no returns.

Made In The USA.