Description

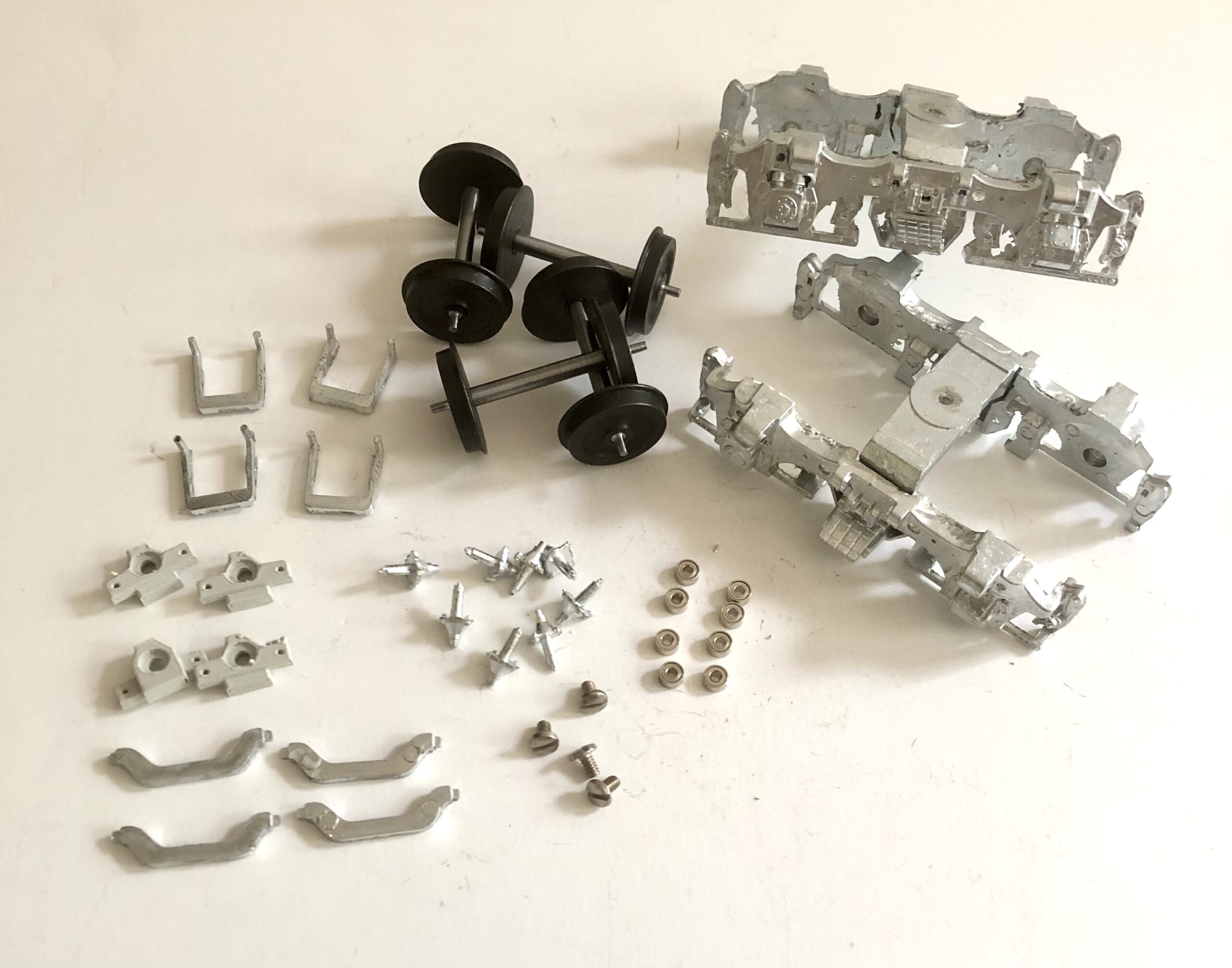

For Sale: All Nation Blomberg Truck Sideframe Kit Unassembled With or Without Axles/Wheels you chose PN#292AN

(the partly assembled trucks in the photos are for demonstration purposes only. This item is a kit.)

This kit is basically the original #2419 without wheels for those modelers that may already have wheel/axle sets and or may be interested to install our drive truck transmissions and gear box units to power their engines or we offer this kit with assembled axle/wheels.

The All-Nation trucks now In-Stock are Die Cast in Zinc using the original Atwater molds for F7/F3 A and B engines. In collaboration with Monarch Railroad Supply we also have bottom operated couplers for the engines.

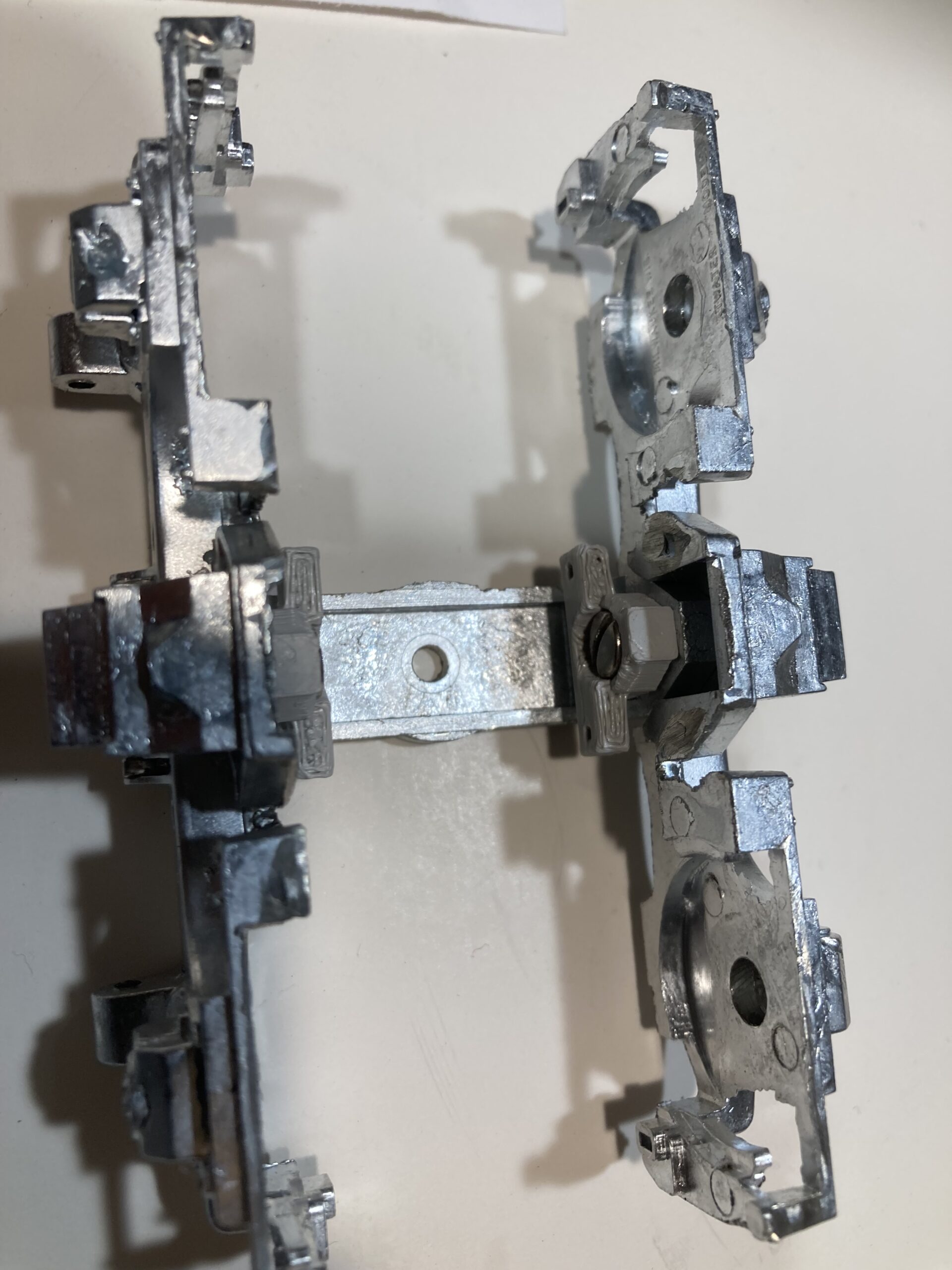

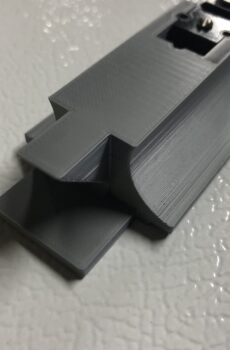

These side frames are pre-drilled in our drill die such that the hangers and air cylinder hardware can be mounted. As in the past, these are fresh out of the die cast mold and requires the modeler to clean up the flash with a file. The kit no longer comes with the bronze journal bushings (#1013), rather we supply ball bearings that go into the journal. The journals are machined to house the bearings. As always, we look to make improvements, consequently we have changed the way the bolster mounts to the side frames. In the past a metal clip (C02032) or cotter hair pin was used in the stud that protrudes outward through the bolster saddle on each side. Now we drill the stud for a 4-40 pan head 1/4″ screw and we use a poly-carbonate part to provision an all wheel pickup for 2 rail dc pickup.

The kit can be used for non-powered engines or our power truck transmissions can be installed for a powered engine. Our standard axles are turned down slightly for the ball bearings and our 40″ wheel sets are available as well. The poly-carbonate bolster part that mounts on top of the inside center side frame stud has holes on either side for 0-80 screws to attach wheel wiper for electrical pickup required for powered units and serves to insulate the truck from electrical shorting across the side frames through the bolster.

Parts List:

Parts for a complete pair of trucks less axles and wheels include the following:

4 Side Frames Part# 101A

2 Bolsters Part# 1004

4 Side Frame Sway Bars Part# 1111

4 End Bars Part #103

4 Swing Hanger over Elliptical Leaf Spring Assembly

8 Air Brake Cylinders

4 Poly-carbonate (PC) bolster mounts

4 4-40 Pan Head screws for PC bolster mounts

8 Ball Bearings

With Axles/Wheels Assembled:

Axles (4)

40″ Wheels (8)

The 40″ Wheel Set (1 pair) Assembled is for the All Nation F3/F7 or NW2 locomotives for 2 Rail O Scale operation for unpowered engine units. Part #1524 is our standard axle used in the All Nation Blomberg truck side frames. One wheel on each axle has the required insulator for 2 rail DC power and must be opposing to avoid a short circuit. Thus, one hole is larger to accommodate the plastic insulator insert for use when pressing the wheels onto the axle. Also sold separately PN#356AN

Instructions for assembly:

All parts freshly minted from die casting requires the modeler to first clean up all the sprues, flash and runners. If you are not sure what this is exactly see a great explanation at:

https://blog.mrt-castings.co.uk/blog/sprues-flash-and-runners-explained

The next step is to process the bolster and fit it over the stud that projects from the center inside side frame with the 4-40 tapped machine screw hole. Some light filing is required to hand fit the end of the bolster over the stud and it must be a snug fit with a little of rotation play.

Take the side frames and bolster apart and use a very light coat of Loctite Stik’n Seal Outdoor adhesive to paint it on the inside of the journal wall to hold the bearings in place while doing the rest of the assembly. Let it dry but do not get the adhesive on the bearing race itself. Only a very light application is needed on the side walls of the journal and then gently set the bear in the journal.

Air Cylinders and swing hangers can be installed on the side frames.

Upon installing wheel sets, make sure the insulated wheels are inserted on the same side frame. Take 1 side frame in hand and mount the bolster with the 4-40 pan head screw making sure the poly-carbonate mounts over the stud and the pan head screw sinks into the recess on the mount. If the pan head screw were to touch any electrical wheel wipers for pickup, the truck will short out, thus the recessed head of the screw.

Next, hold the side frame with the bolster in hand with the wheel set seated in the bearing and bring the 2nd side frame up to just start it onto the stud at which point you will put the sway bar in one end while starting to squeeze on the 2nd side frame then adding the other sway bar. Once those parts come together, the 2nd 4-40 screw and mount can be drawn and snugged up. There should be a little rotational play in the bolster but the mounts are tightened enough such that the sway bars on the ends of the side frames do not fall out.

Made In The USA.