Description

For Sale: All Nation NW2 Power Truck Tower Transmission Drive – Assembled PN#303AN

(other photos and videos are for reference only, but are available for purchase, too)

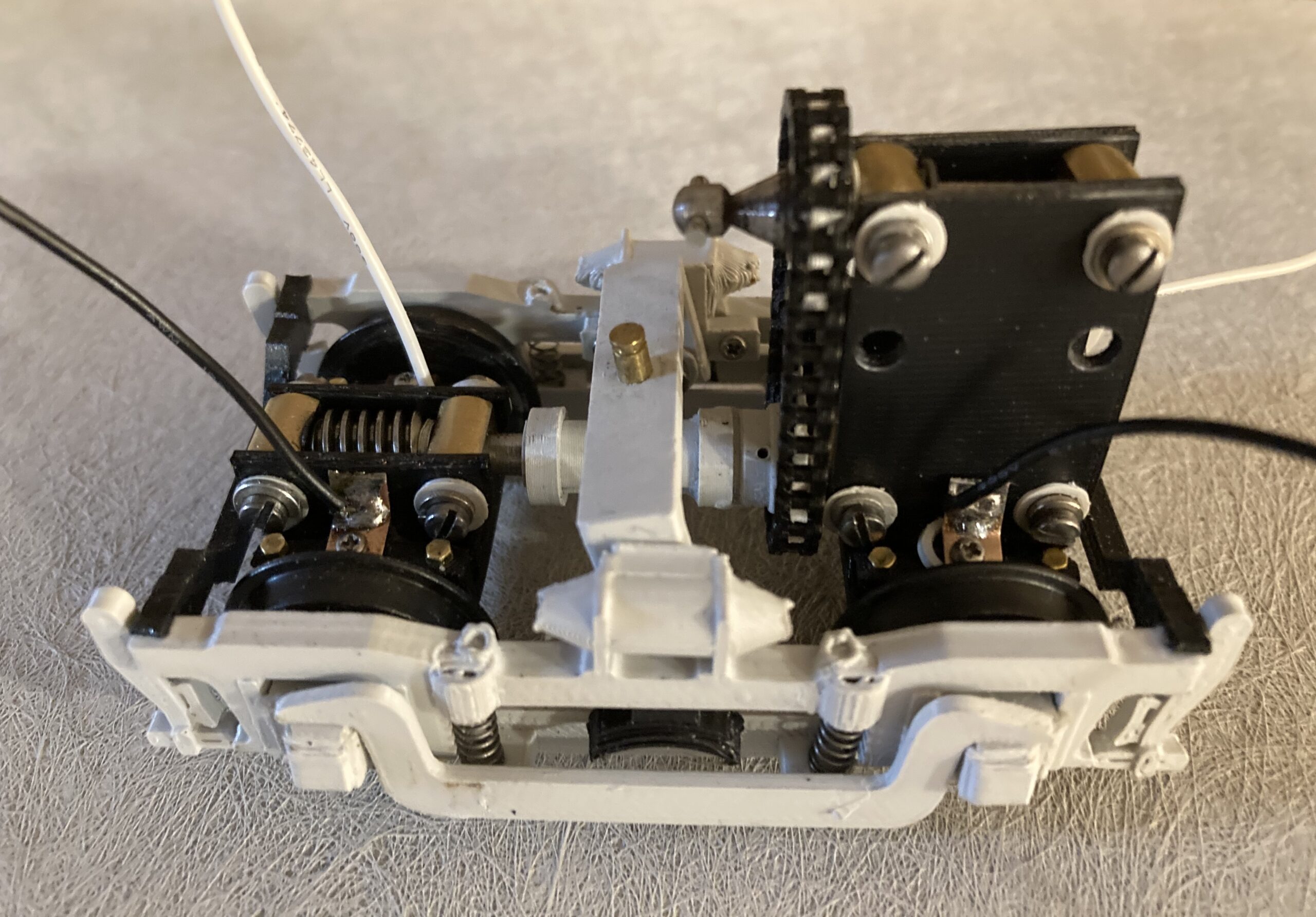

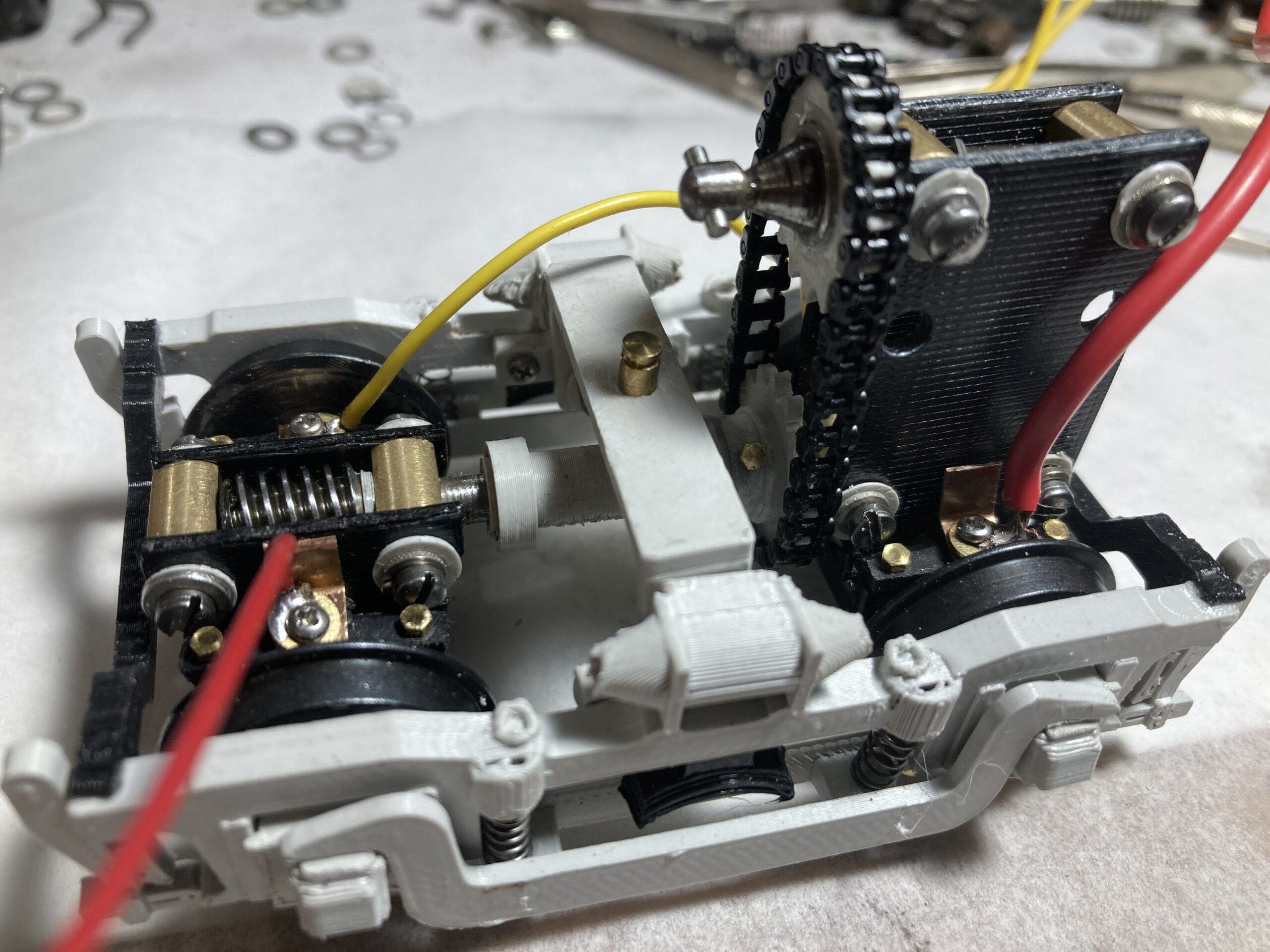

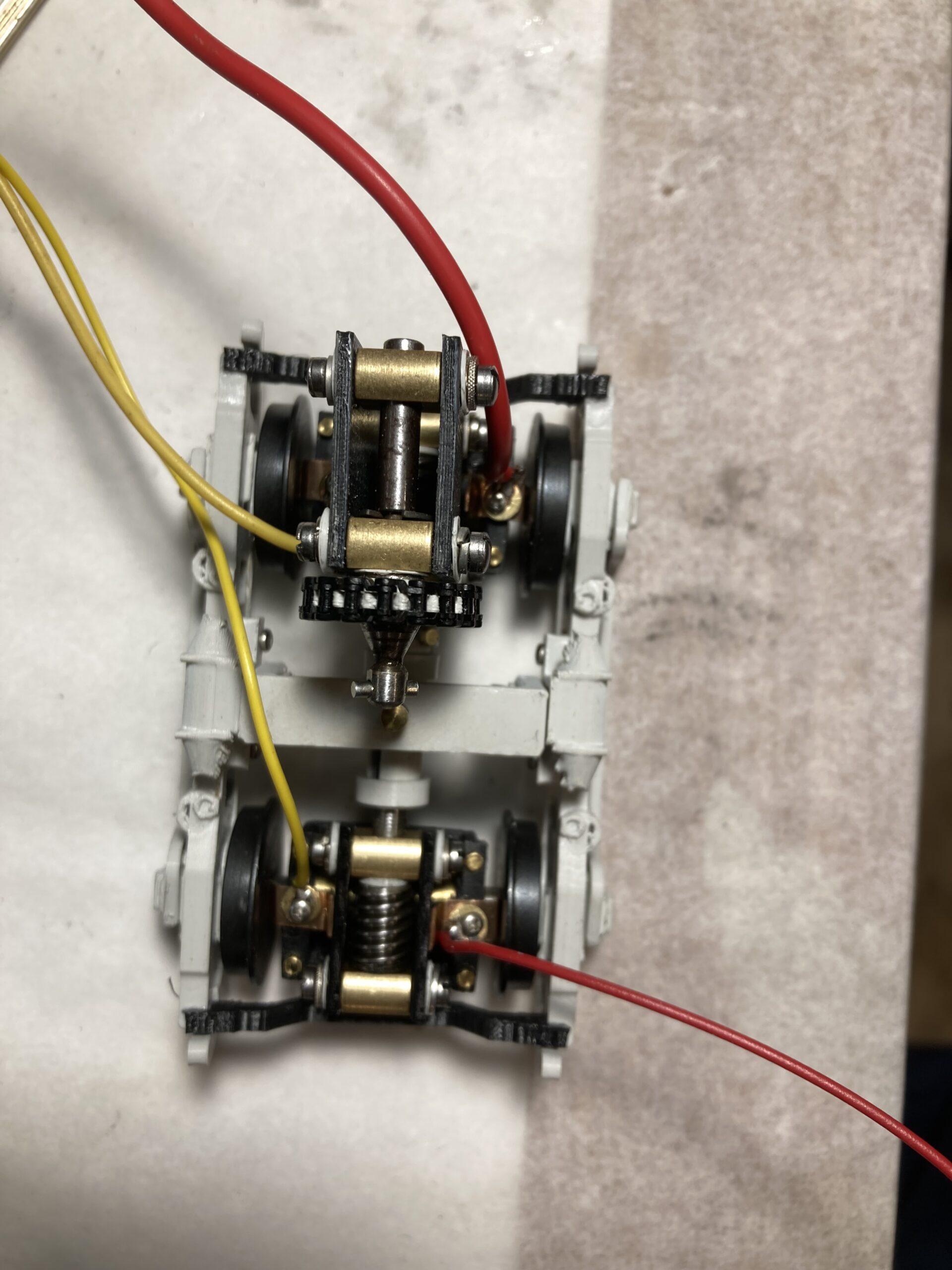

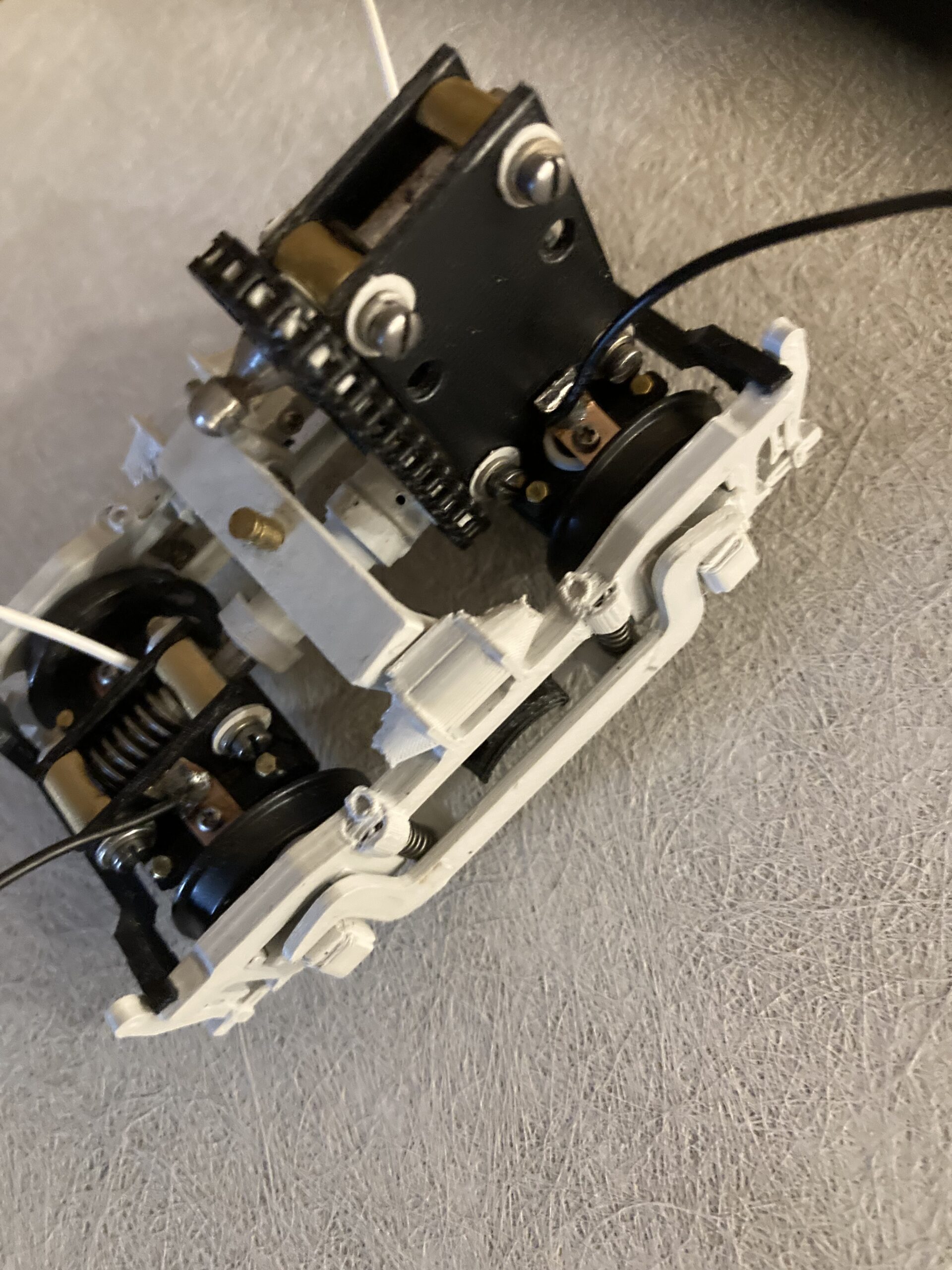

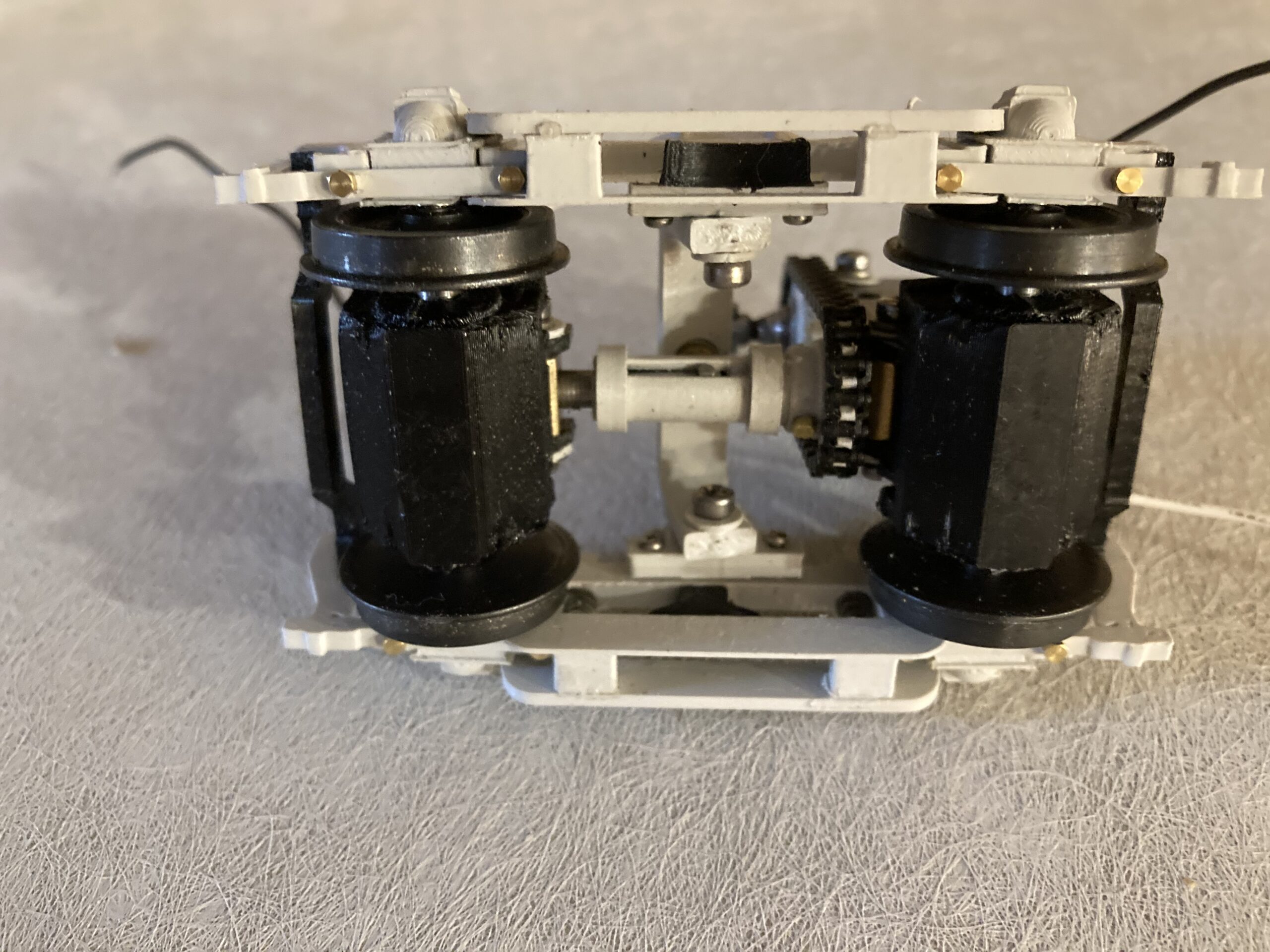

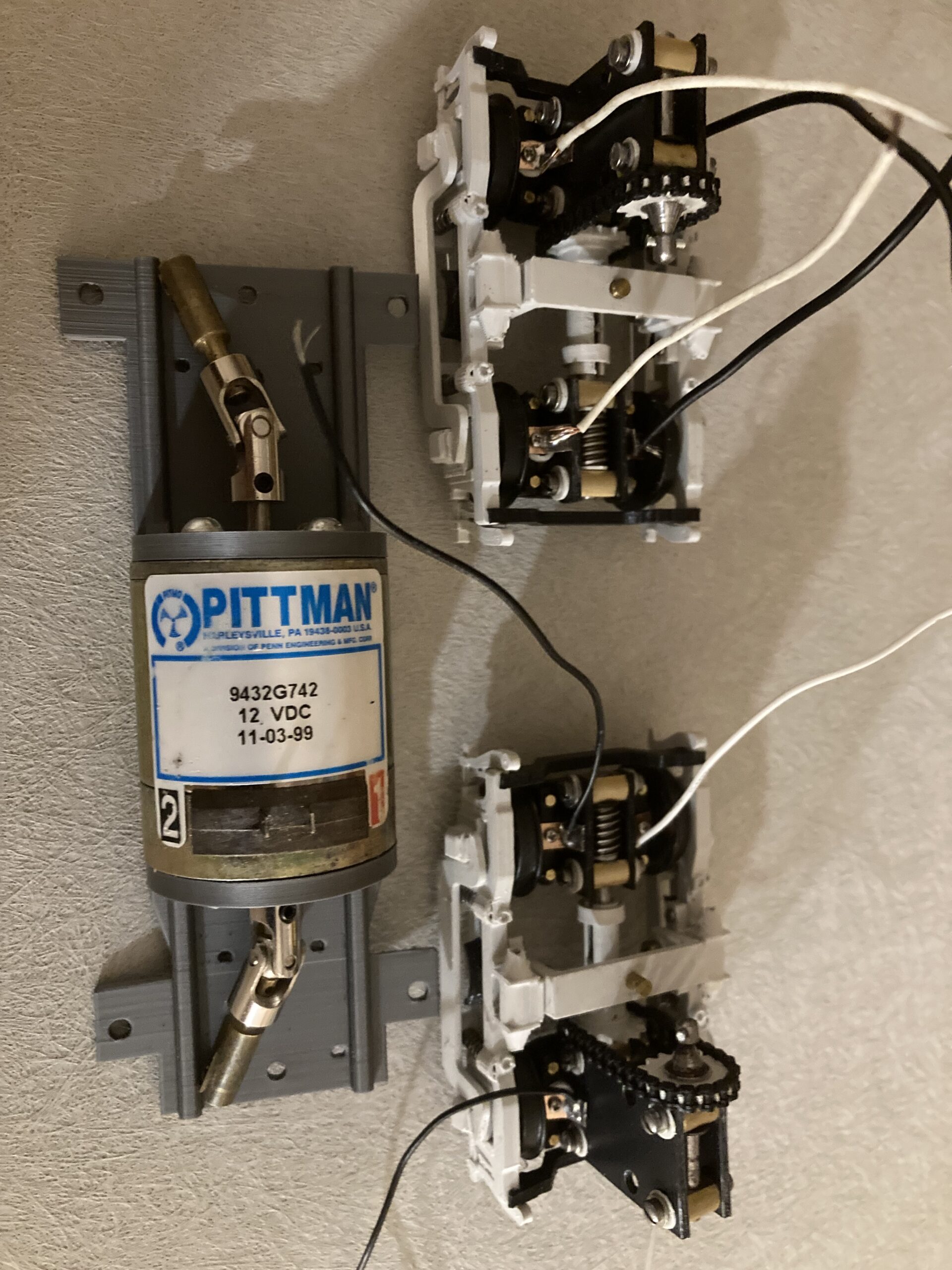

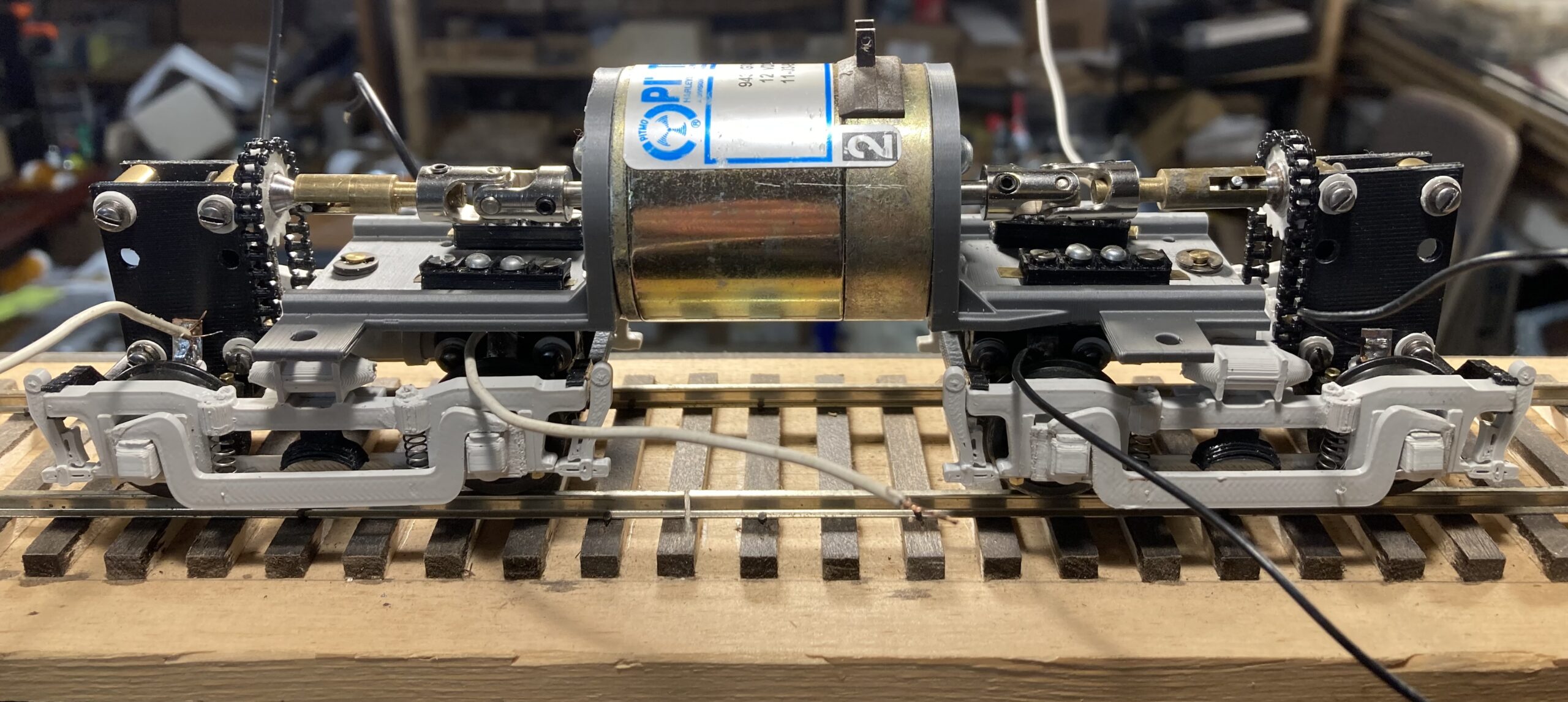

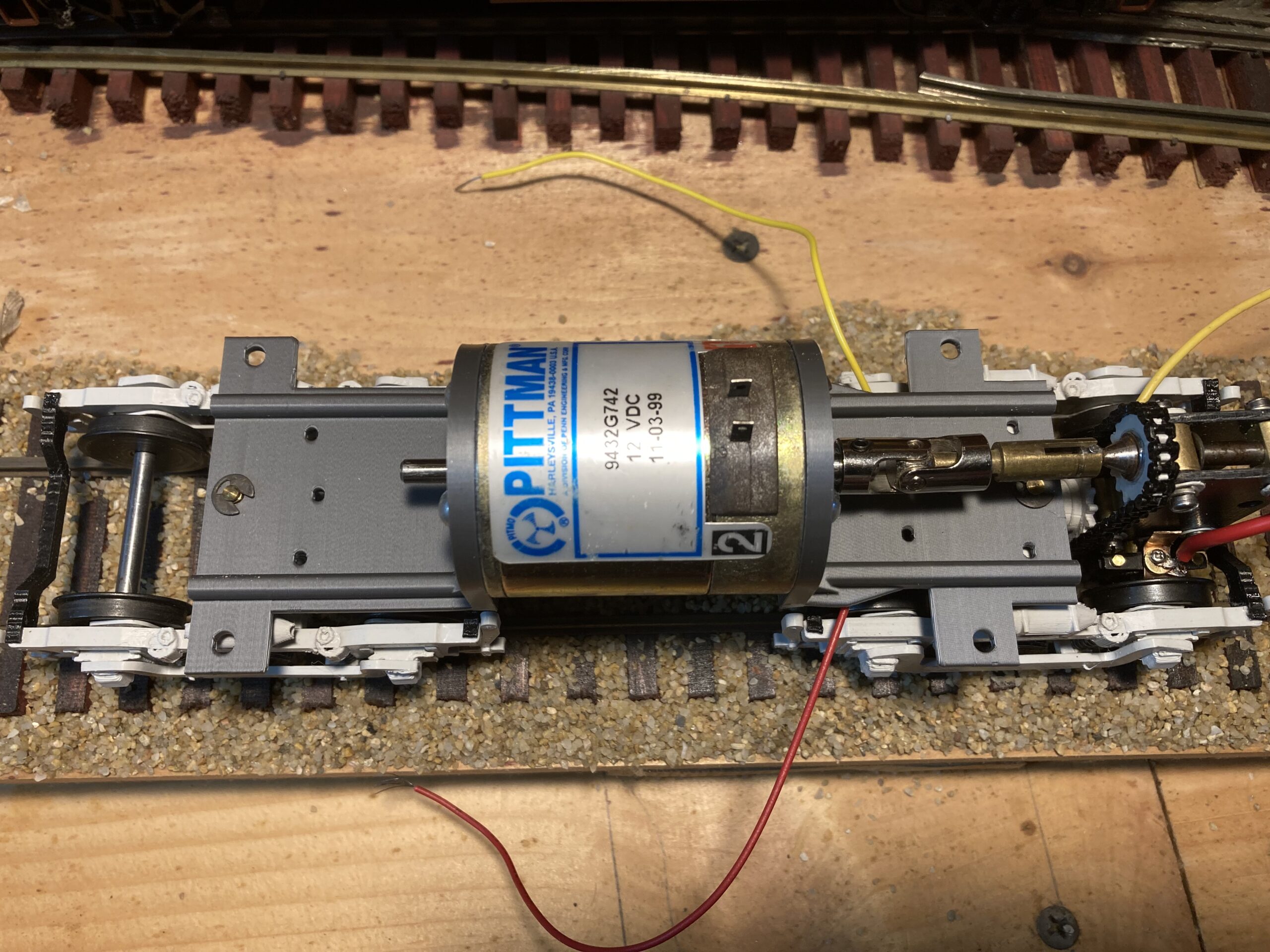

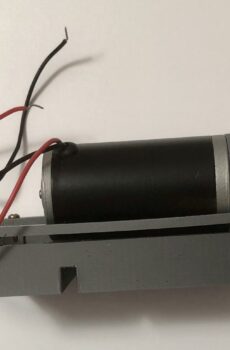

The power for the All Nation NW2 locomotive has been extensively re-engineered on the basis of the original mechanical drawings using the new technologies of the day. We created a better looking and functional AAR Type A truck with ball bearings and working suspension springs in the side frames. The tower drive now comes in several different heights to align with the motor shafts with less resistance on universal joints. The All Nation NW2 1000 HP still requires the lower standard tower drive in order for accommodating internal body clearances. However, the intention is to be able to utilize the various height transmissions in other engine models where adequate clearances allow.

One of the unique features not found in other models is the ease of maintenance. The entire mechanism can be taken apart and easily re-assembled for future upkeep. Replacement parts are available. Our tower transmissions are also adaptable to other engine models.

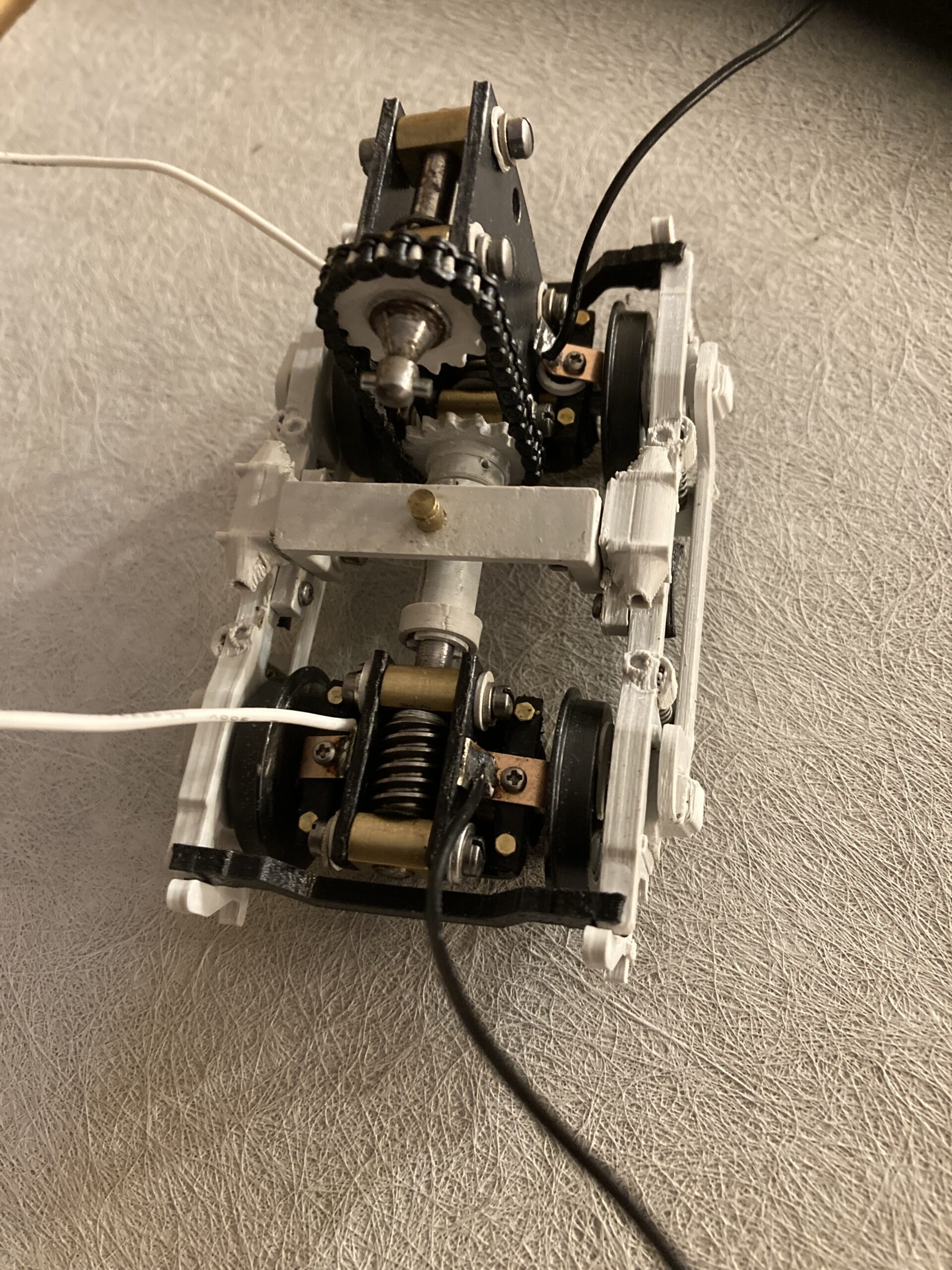

The tower drive is chain driven on our sprockets using our special Poly Carbonate ABS filament blend. The sprockets should not crack or fail like the older Delrin or Nylon seen in the past and in other brands of engine power implementations. The gear box sides #4038 and #4039 are no longer steel. Rather we print and stamp them out of Poly Carbonate making for a quieter mechanism.

To give you a better idea on how I have upgraded my NW2 engines, please view the following video:

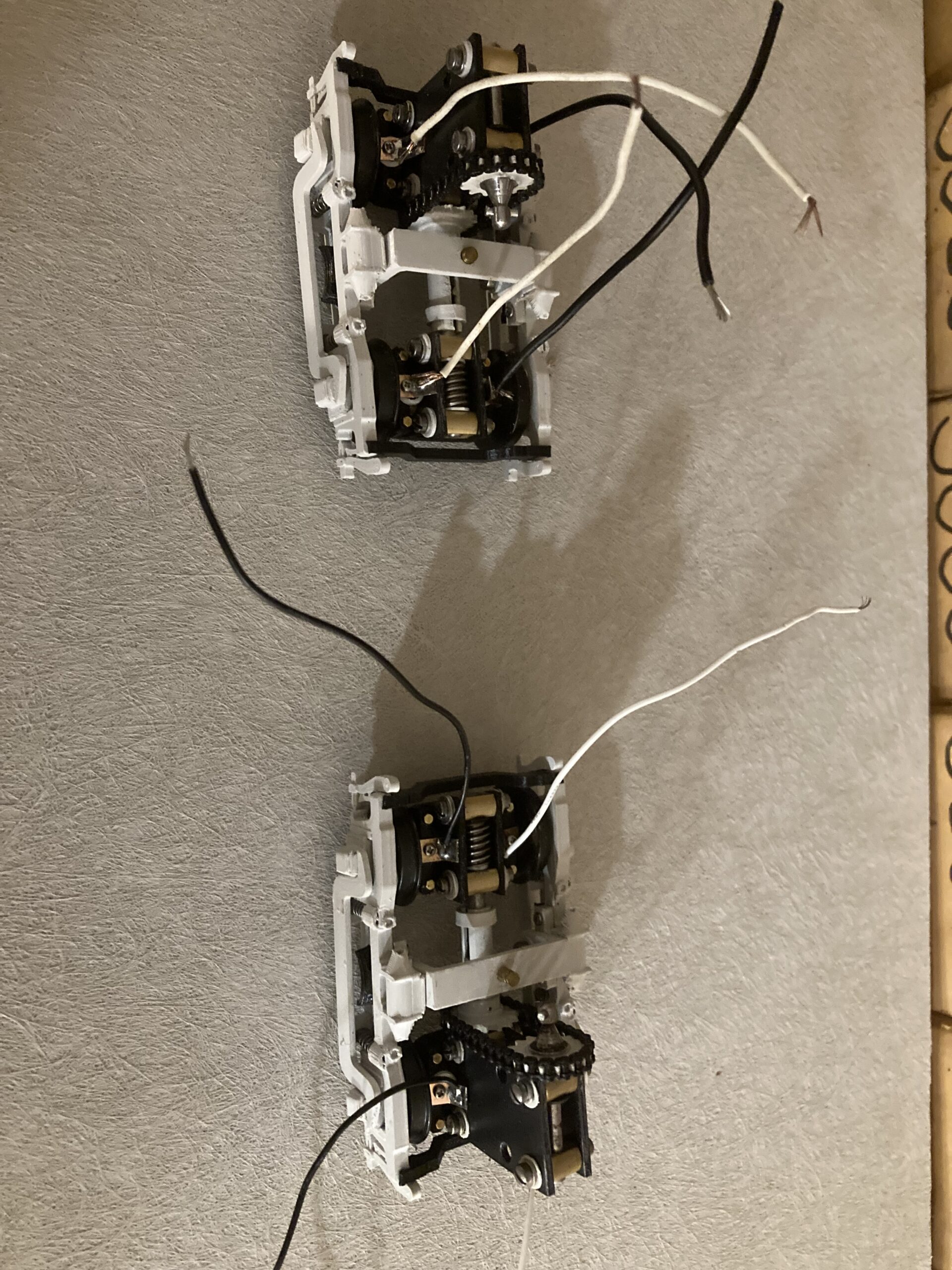

Note, in the video illustrating the taller towers, the mechanism under test will not fit in the All Nation NW2 body due to internal clearances requiring the short tower transmission.

Included for your reference are several close up photos showing in detail the tower drive with the small gear box using the 1 piece 3D printed shaft coupler/sprocket on the end of the tower worm shaft.

We can also take custom orders for retrofitting our transmissions in longer wheel base locomotive trucks. This transmission configuration also fits perfectly in our F3/F7 EMD Blomberg trucks.

This assembled kit is available in kit form as well. The modeler should have some of the right tools in the model shop and skills to do the assembly work as this is a hand crafted piece of work.

Dual power trucks can be used in the NW2 Switcher engine. In my case the one tower transmission in the front end of the engine is adequate.

We should note that one side of the wheel sets are insulated with a bushing however given the use of our gear covers we have implemented all wheel electrical pickup for 2 rail DC operations. The pickups can be removed if one were to go with Power On Board i.e., battery operated models, also known by modelers as Dead Rail since power is no longer supplied to the rails if running off of batteries.

The following is a parts list break down for the 3 kits that make up the assembly of this power transmission truck consisting of approximately 120 parts in total.

Parts List:

AAR Truck Type A Parts List

2 Frames with coil spring assemblies

2 Sway Bar End Frames

4 Coil Springs

2 Leaf Spring Assemblies

1 Bolster

2 Bolster Bushings

4 Side Frames, considered hollow when assembled

2 4-40 x ¼” Fillister Head Bolster Screws

4 Clasp Air Brake/Adjusters

2 Right Side Journal

2 Left Side Journals

2 Air Brake Cylinders

4 Axle Ball Bearings

4 0-80 x 3/16” Pan Head Philips screws for Air cylinder mounts

8 00-90 x 3/16” Slack Adjuster mount screws

1 Air Cylinder Brake Rod

The breakdown of parts for the small gear unit follows:

Parts List PN#9027 (aka 4062) Kit Constant Torque Transmission

1 Drive Shaft PN#4045 1-3/4″ Long

2 Spacer Bushing For Drive Shafts PN#4040

1 Spur Gear i.e. Worm Gear for Axle PN#4052

2 Brass Axle Bushings PN#4073

1 Axle PN#1524

4 3-48 x 5/32″ Filister Head #C1301

4 Thrust Washers aka Shim Rings

2 40″ wheels PN#2146 and PN#2147 (note may be substituted for 33″ or 36″ wheels) depending on your application

2 Wheel Insulators

4 Lock Washers #C2034 or C2031

1 Worm #4051

2 Gear housing Side Panels PN#4039

1 Bottom Spur Gear Pan with 2 Retainers & 4 Screws 0-80 x 3/16 Screws 3D Print PN#253AN

The breakdown of parts for this tower gear unit follows:

Parts List PN#9056Chain (aka 4056) Constant Torque Transmission Blueprint Section A

#4056 Blueprint Section A

1 Drive Shaft PN#4045 1-1/4″ Long plus pin

4 Spacer Bushings For Drive Shafts PN#4040

1 Spur Gear i.e. Worm Gear for Axle PN#4052

2 Brass Axle Bushings PN#4073

1 Axle PN#1524

8 3-48 x 5/32″ Filister Head #C1301

8 Lock Washers #C2034 or C2031

5 Thrust Washers aka Shim Rings

2 40″ wheels PN#2146 and PN#2147 (note may be substituted for 33″ or 36″ wheels)

2 Wheel Insulators (1 is a spare)

1 Worm #4051 (Worm may already be pressed onto shaft #4045)

2 Gear housing Side Panels PN#4039

1 Bottom Spur Gear Pan with 2 Retainers & 4 Screws 0-80 x 3/16 Screws 3D Print PN#253AN

1 Upper Drive Shaft with ball #4042

1 Lower Drive Shaft Coupler #4041

1 PC/ABS Sprocket 16 teeth Upper Drive Shaft #S123 to be mounted on #4042

1 PC/ABS Sprocket 16 teeth Lower Drive Shaft #S154 to be mounted on #4041

1 Chain 4” long

1 Upper Drive Shaft C Clip #C2036