Description

All Nation Line NW2 Motor Rehab Kit 244ANK

For Sale: A couple of my older AN NW2 switcher engines were inoperable due to the old motor malfunction and or missing linkage between the motor and the geared tower drive to the powered truck. In order to repair and restore my engine, we designed an easy drop in replacement kit to get back up and running. In this case, the power truck was in good condition without any worm gears binding.

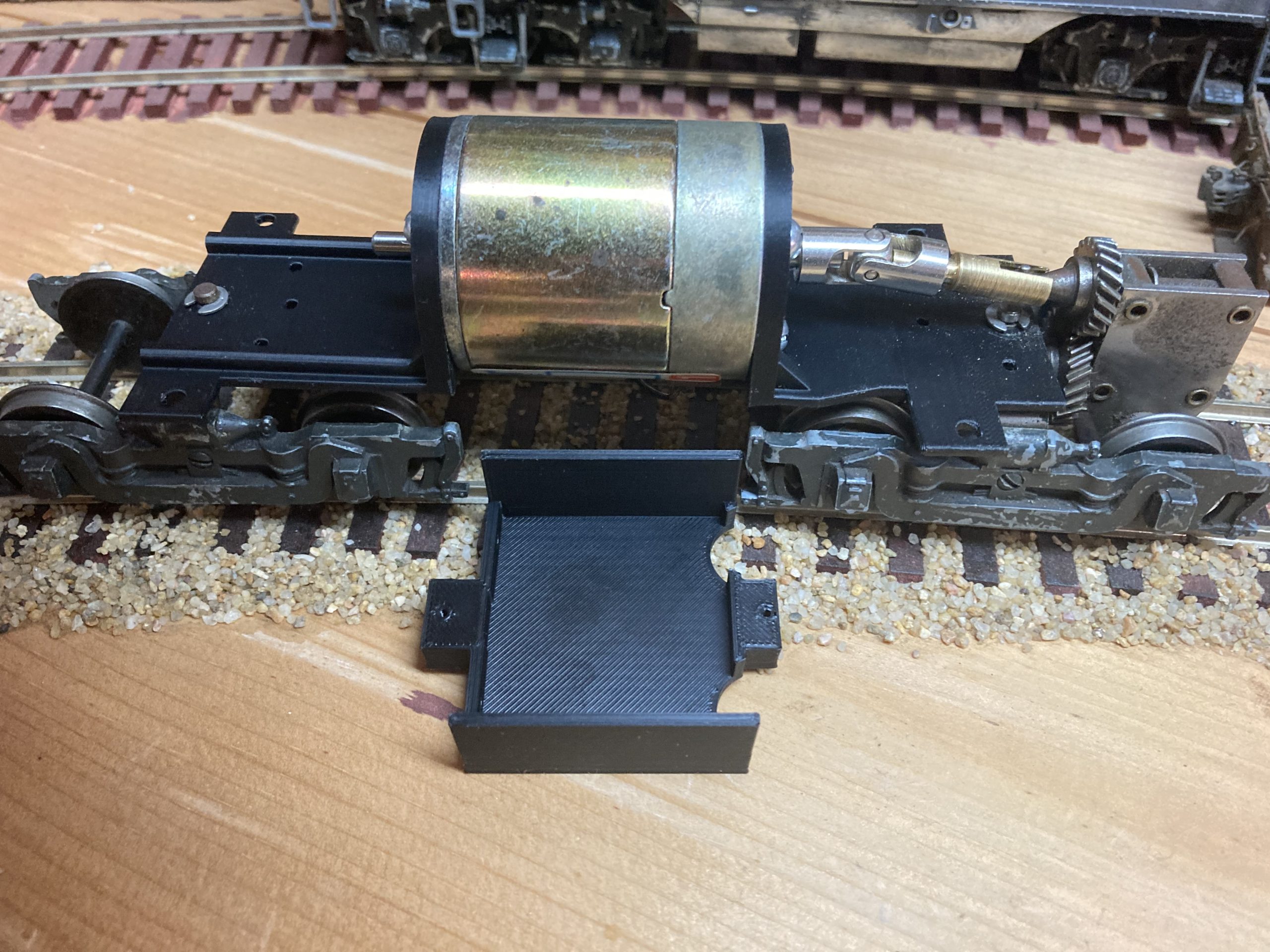

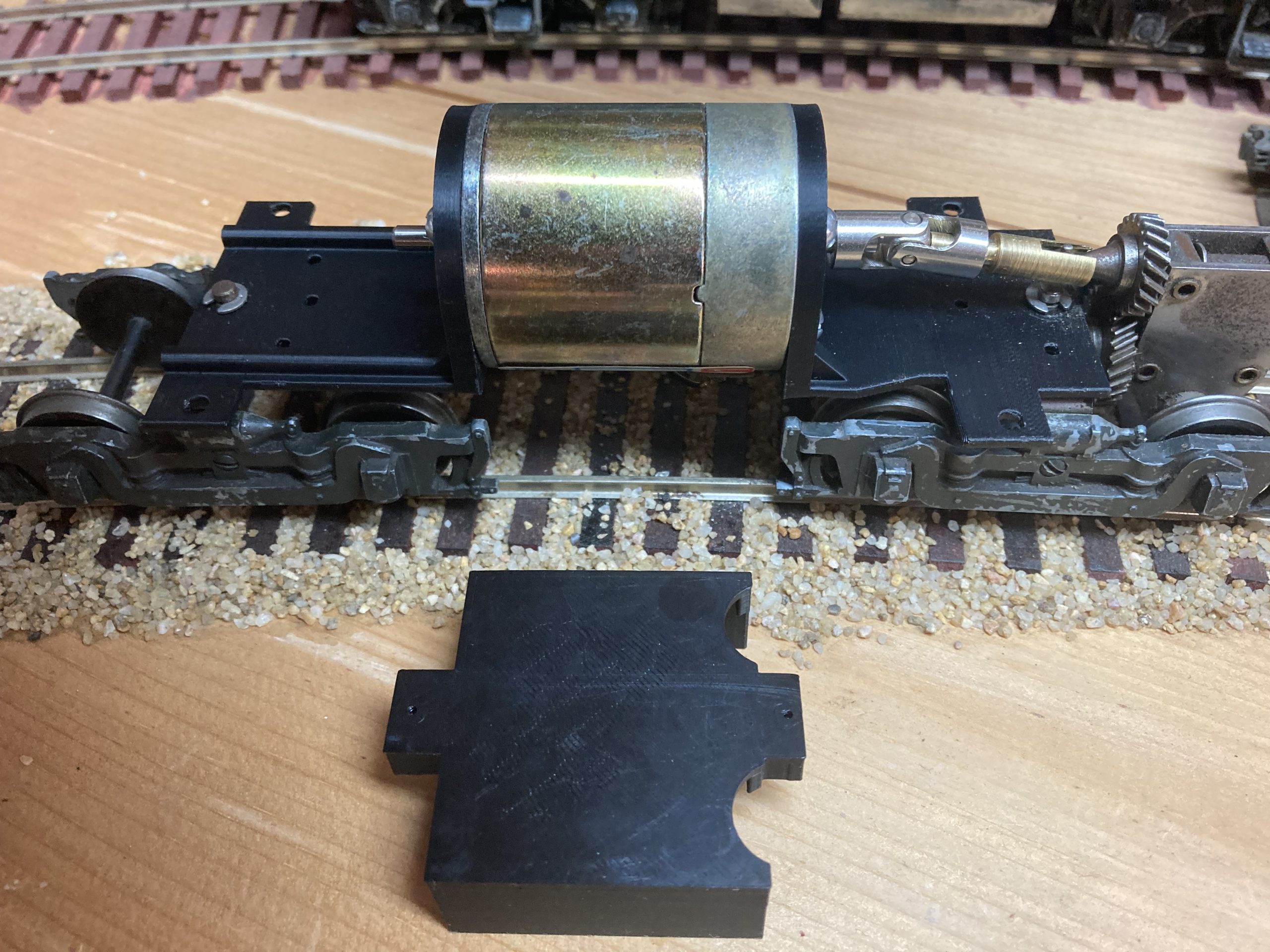

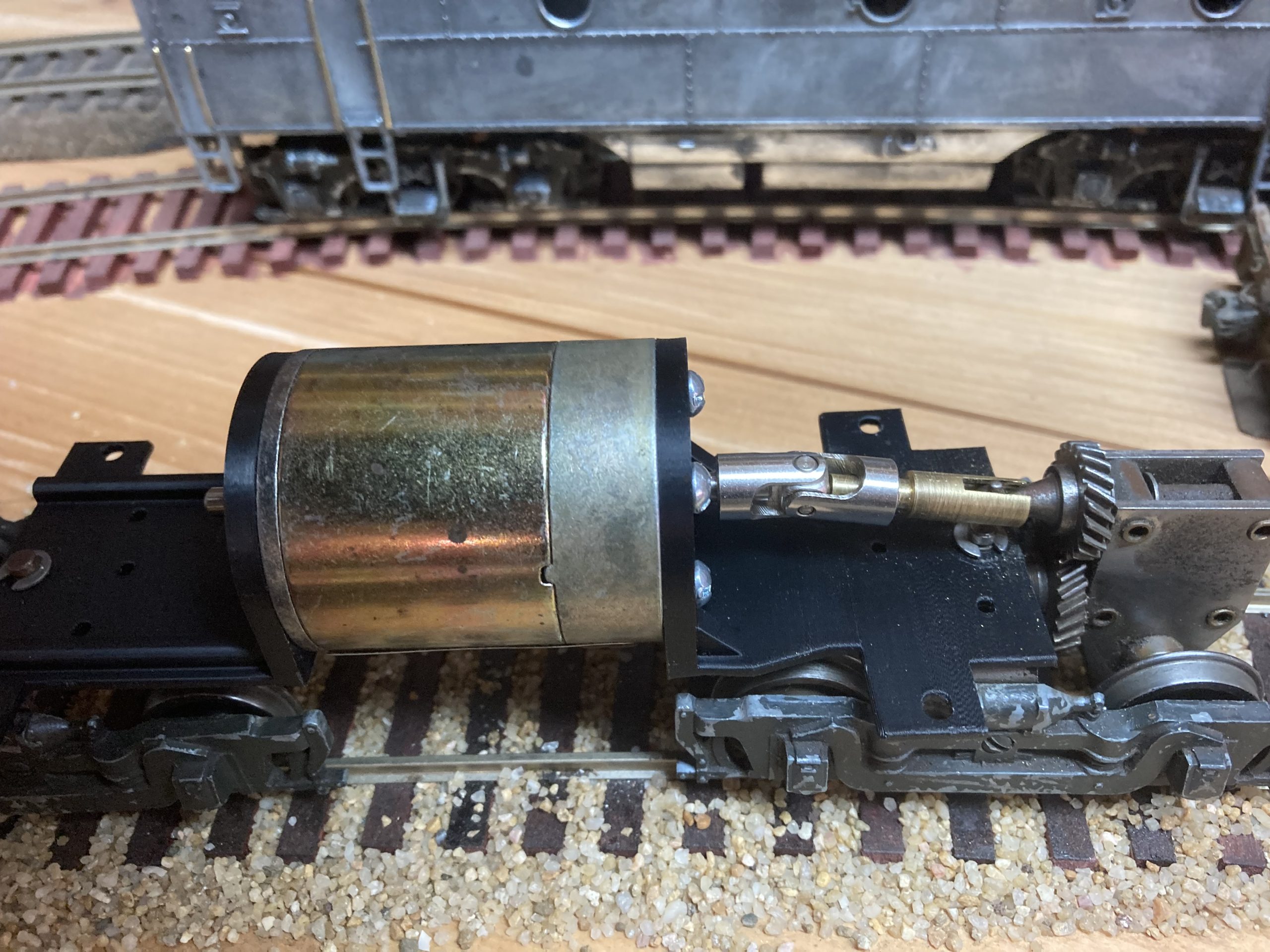

This kit is for a single power truck drive with the tower gearing located in the cab end of the engine body. Our design once assembled and trucks remounted with the king pin and C clip(s), the unit drops into place and is screwed down with 2 4-40 flat head screws for both platform ends for a total of 4 screws. The motor is a 12 volt DC Pittman (Old/New Stock) so we make no warranty on the performance or motor lifetime. The power transmission from the motor to the geared drive tower is achieved with 1 precision universal joint. The motor measures a diameter of 40 mm and the length is approximately 46 mm.

The kit requires removal of the original All Nation motor and aluminum mounting rails as well as the bakelite platforms that the trucks mount to. Detach the trucks from the platforms by taking the C Clip off the king pin and save those parts for later re-installation.

Tools required for this project include a screw driver and possible use of a Dremel with a mandrel and cutting disk.

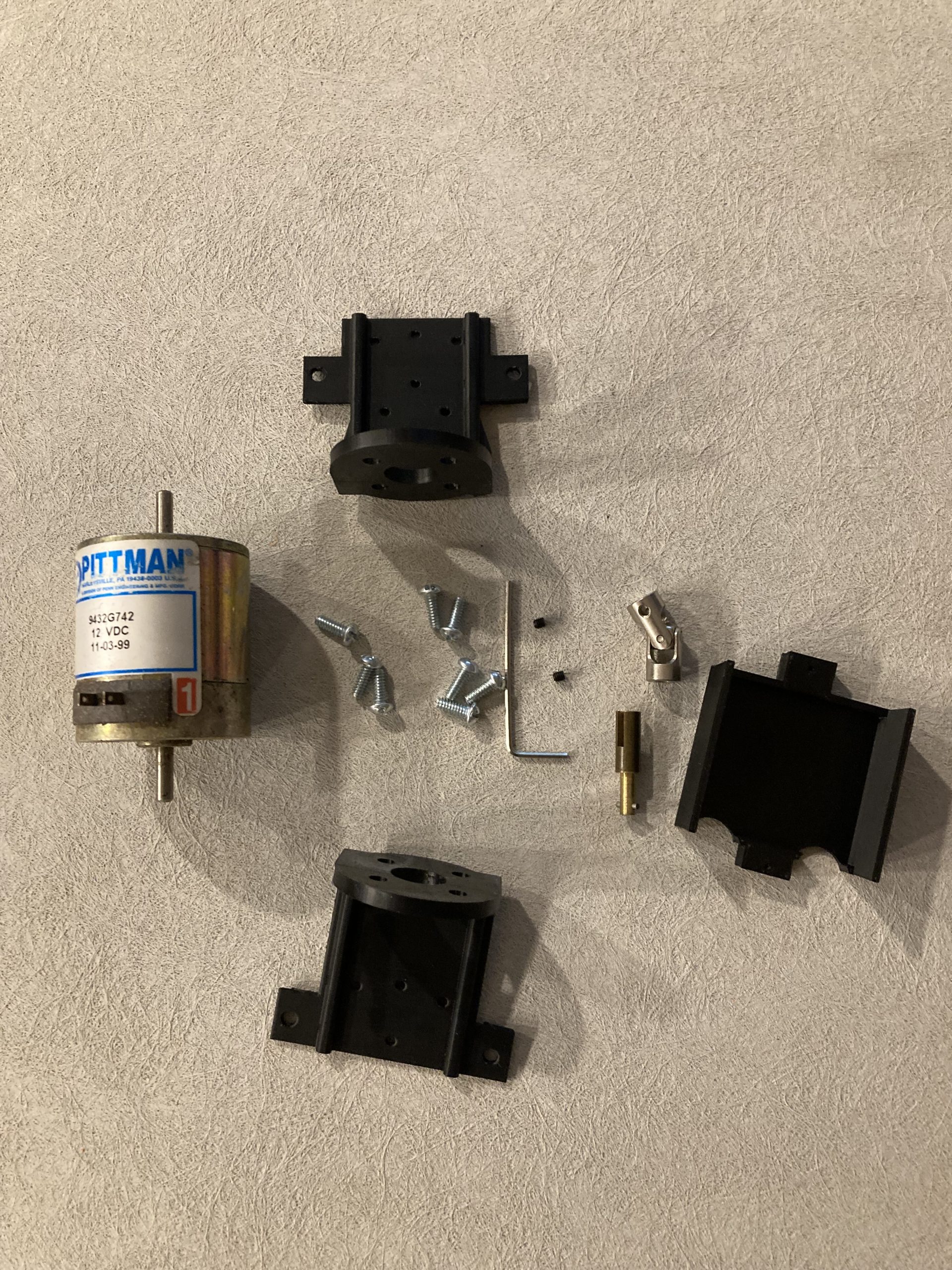

The parts list follows included in this purchase:

2 ABS 3D Printed platforms for mounting the motor and ultimately the trucks.

1 ABS fuel tank motor cover.

1 Pittman 12 vdc Motor.

8 6-32 machine screws to mount the motor in place.

1 Universal Joint with 2 tiny set screws & 1 Allen wrench to tighten the set screws once the drive shaft lengths are determined.

1 brass split shaft coupler to connect to the tower round ball with the pin located in front of the gear.

4 4-40 brass flat head machine screws.

The brass split coupler will need some modification to include removing the steel pin, slightly resizing the internal diameter of the shaft to accommodate the tower gear ball and possibly shortening the shaft 3 or 4 millimeters. The ball should slide in easily and be able to rotate when the tower turns when the engine takes a curve in the road bed.

Thus far, we have been testing the performance of the mechanism at various speeds both as a road engine and switching scenarios and have been pleased.

One caveat, if your engine bolster is not standard All Nation brass king pin and clip to mount the trucks on the tower drive platform, this kit may not work due to the close clearances of the platform under the drive shaft immediately ahead of the tower gear. The hole in which the king pin is located on the platforms will need to be drill to the correct size to accommodate the king pin as we do not assume your engine is original equipment. The king pin situation may have been modified over the years or changed out. In any event, the modeler needs to check the clearances. The reinstall of the original lead weight may not work after this rehab work is finished. This kit will not overcome any other problems with the tower drive gearing or truck assembly mechanism as these need to be in good working order.

We hope you enjoy this easy to build kit with a mechanism that is serviceable in the future.

Consider viewing more on this item in the video at the following link: